The Best 10 Pressure Gauges for Accurate Measurements?

Pressure gauges play a crucial role in various industries, ensuring accurate measurements for safety and efficiency. According to a recent report by MarketsandMarkets, the global pressure gauge market is projected to reach $5.2 billion by 2027. This growth indicates the rising demand for reliable measurement tools across sectors like oil and gas, manufacturing, and healthcare.

However, not all pressure gauges provide the same level of precision. The industry faces challenges with calibration and accuracy. A poorly calibrated gauge can lead to significant errors, resulting in costly mistakes. For instance, inaccurate pressure readings in manufacturing can compromise product quality. The need for consistent performance highlights the importance of choosing the right model.

With numerous options available, selecting the best pressure gauges requires careful evaluation. It's essential to consider factors like type, range, and environment. Many users overlook these details, leading to suboptimal choices. This article will guide you through the top 10 pressure gauges, ensuring you make informed decisions for accurate measurements.

Understanding Pressure Gauges: Types and Uses

Understanding pressure gauges is essential for accurate measurements in various applications. These instruments measure the force exerted by a fluid or gas. Common types include analog, digital, and manometers. Each type serves a specific purpose and offers different features. Analog gauges provide a visual display, while digital ones often show readings in real-time. Manometers, on the other hand, are useful for measuring low pressures, usually in closed systems.

Choosing a pressure gauge requires careful consideration. Factors like the measurement range and the environment impact performance. For example, extreme temperatures can affect accuracy. Many users overlook calibration, which is crucial for reliable results. Regular checks can help maintain gauge precision, yet they are often neglected.

A pressure gauge must fit the application. Not all gauges work for all situations. Customization or modifications may be necessary, which can complicate the process. Some users may struggle with understanding specifications, leading to mismatches. Clearly understanding types and uses helps avoid these pitfalls. Accurate pressure measurements are vital, and selecting the right tool is crucial to achieving them.

Key Features to Consider in a Pressure Gauge

When selecting the right pressure gauge, several key features stand out. Accuracy is paramount. A gauge needs to provide precise readings to ensure safety and efficiency. Look for models that promise high accuracy specifications.

Calibration is another critical factor. Regular calibration ensures the gauge maintains its accuracy over time. Neglecting this can lead to faulty readings.

Material construction also matters significantly. Durable materials can withstand varying conditions. Stainless steel is a popular choice due to its resistance to corrosion. However, some gauges may require protective coatings, especially in harsh environments.

Consider the size and scale as well. A transparent display can enhance readability, but oversized gauges may complicate installations in tight spaces. Pressure range is vital too. Ensure the gauge matches your specific pressure needs. A gauge with too broad a range may lack resolution. Meanwhile, gauges with narrow ranges may not capture larger pressure spikes.

Flexibility in mount type adds convenience. Some gauges can be wall-mounted while others are handheld. Choosing the right mounting option often depends on frequent accessibility needs. Thoughtful selections can greatly enhance your workflow.

Top 10 Pressure Gauges for Precision Measurements

Pressure gauges play a vital role in various industries. Accurate measurements are crucial for safety and efficiency. According to a recent industry report, nearly 30% of equipment failures are linked to pressure measurement errors. This highlights the importance of selecting the right gauge for your needs.

Precision pressure gauges come in many forms. Digital gauges offer quick readings with high accuracy. They can measure pressure with tolerances as tight as 0.5% of full scale. Mechanical gauges, while often simpler, can also provide reliable readings. However, they may struggle in extreme conditions. Regular calibration is necessary for both types to maintain accuracy.

Businesses often overlook the need for proper maintenance. A gauge that isn’t calibrated may lead to serious issues. According to industry studies, up to 15% of pressure gauges fail to perform consistently over time. This inconsistency can have costly implications. Investing in quality tools and performing regular checks can mitigate these risks.

Comparing Accuracy and Durability of Selected Models

When selecting a pressure gauge, accuracy and durability are key factors. An accurate gauge provides reliable readings, which is essential for many applications. Durability ensures the gauge can withstand harsh conditions without compromising performance.

Some models excel at both accuracy and durability. For instance, stainless steel casings can protect against corrosion. This feature is crucial for gauges used in humid environments. However, not all models maintain accuracy over time. Some may drift after heavy usage. Regular calibration can address this issue but requires extra effort.

Another aspect to consider is the scale of measurement. Analog gauges may offer quick readings but can be hard to interpret under low light. Digital gauges often provide clearer displays. Yet, they can be more sensitive to temperature changes. The balance between ease of use and accuracy is not always perfect. Each choice comes with trade-offs, reminding us to assess our specific needs carefully.

The Best 10 Pressure Gauges for Accurate Measurements

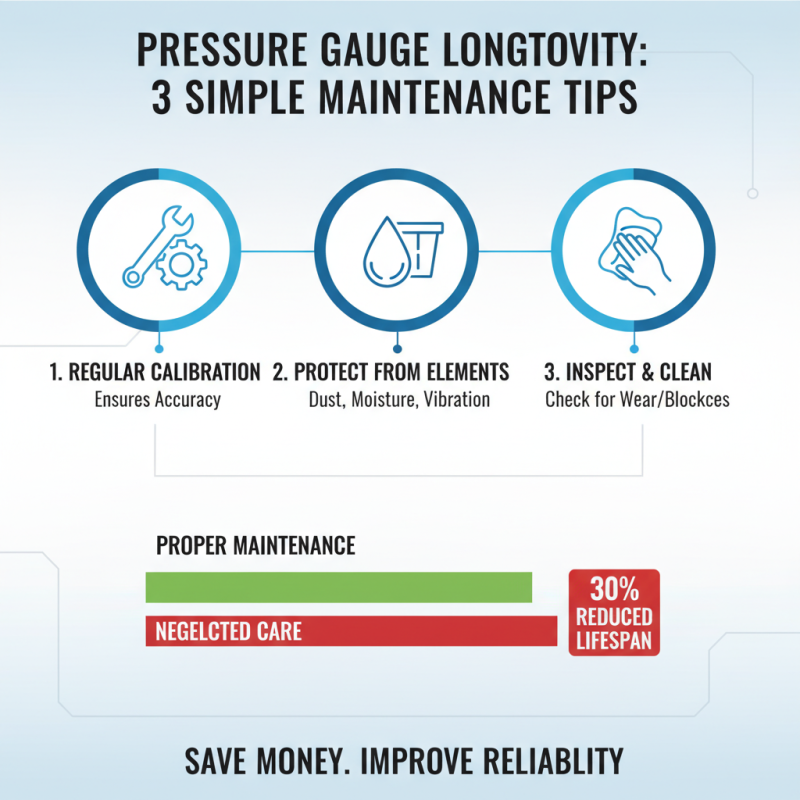

Maintenance Tips for Ensuring Gauge Longevity and Performance

Pressure gauges are essential for accurate measurements in various industries. However, ensuring their longevity requires regular maintenance. Neglecting proper care can lead to inaccurate readings and premature replacement. Reports show that improper maintenance reduces gauge lifespan by up to 30%. To avoid this, follow some simple maintenance tips.

Regularly inspect your pressure gauge for signs of wear and damage. Check seals and connections for any leaks. If you notice any discrepancies in readings, recalibrate the gauge as needed. It's advisable to clean the gauge according to the manufacturer's guidelines. Dust and debris can lead to inaccurate measurements.

Additionally, store your gauge properly when not in use. Avoid exposing it to extreme temperatures or corrosive environments. This can cause permanent damage. Keep a log of maintenance activities. This helps track performance and identify patterns. Monitoring and adjusting based on past data can significantly improve gauge reliability. Implementing these practices not only ensures performance but can also save costs in the long run.

Related Posts

-

Ultimate Pressure Gauges Procurement Checklist for Global Buyers

-

Exploring Innovative Alternatives to Traditional Pressure Gauges in Industrial Applications

-

How to Choose the Right Pressure Gauge for Your Industrial Applications

-

How to Choose the Best Pressure Gauges for Your Needs in 2025

-

Essential Tips for Choosing the Right Pressure Gauges?

-

Exploring the Benefits of Stainless Steel Fittings: Why They Are Essential for Your Home Plumbing Solutions