Why Choose Stainless Steel Ball Valves for Your Plumbing Needs

When it comes to plumbing solutions, the choice of materials is paramount, and stainless steel ball valves have emerged as a top contender in the industry. According to John Smith, a renowned expert in the valve manufacturing sector, "Stainless steel ball valves are not only durable but also provide unparalleled efficiency in fluid control." This encapsulates the growing preference for these valves, particularly in demanding environments where reliability is critical.

Stainless steel ball valves offer numerous advantages, including resistance to corrosion, high pressure tolerance, and a streamlined design that ensures smooth operation. Their robustness makes them ideal for both residential and industrial applications, allowing for seamless integration into various plumbing systems. As users seek long-lasting and effective solutions, understanding the benefits of stainless steel ball valves becomes essential for making informed decisions.

In an era where sustainability and efficiency are at the forefront of construction and renovation, stainless steel ball valves stand out as a premium choice. Their versatility and performance not only enhance the longevity of plumbing systems but also contribute to overall system effectiveness. Thus, for anyone considering their plumbing needs, stainless steel ball valves are worth exploring.

Benefits of Using Stainless Steel Ball Valves in Plumbing Systems

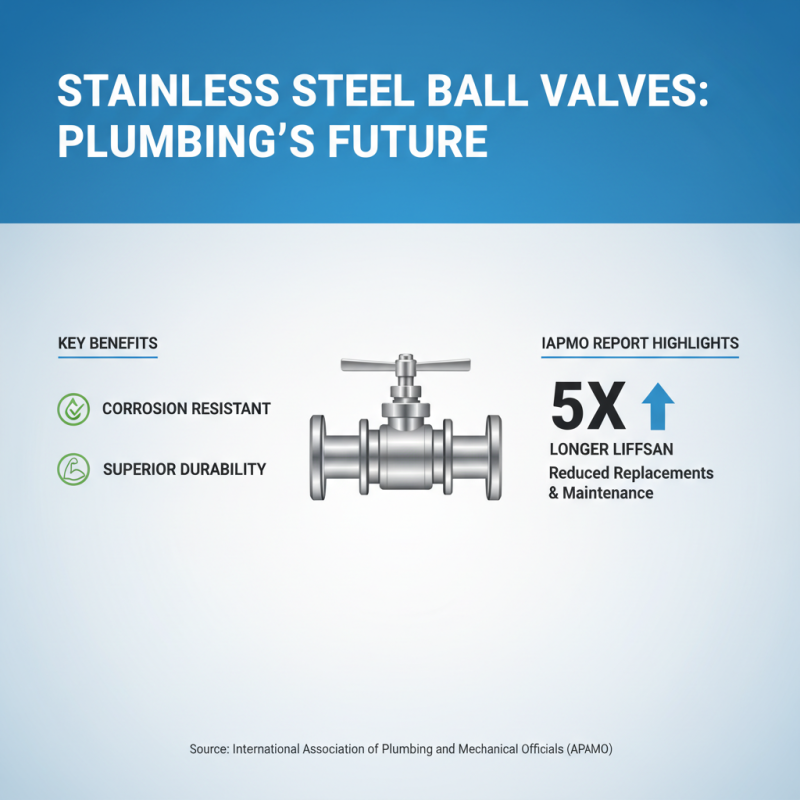

Stainless steel ball valves are becoming increasingly popular in plumbing systems due to their numerous advantageous properties. One primary benefit is their remarkable durability; stainless steel offers superior resistance to corrosion, making these valves ideal for a wide range of applications, particularly in environments where moisture and chemicals are present. According to a report by the International Association of Plumbing and Mechanical Officials (IAPMO), stainless steel components can last up to five times longer than traditional brass or plastic options, significantly reducing the frequency of replacements and maintenance costs over time.

Additionally, stainless steel ball valves provide excellent flow control and sealing capability, which enhances overall system efficiency. The design of ball valves allows for a straight-through flow path, minimizing turbulence and pressure drop. In fact, industry studies indicate that stainless steel ball valves can achieve a flow coefficient (Cv) as high as 100, outperforming many other valve types. This characteristic not only improves the performance of plumbing systems but also contributes to energy savings, as systems do not need to work as hard to maintain pressure, ultimately lowering operational costs for both residential and commercial applications.

Key Features of Stainless Steel Ball Valves Compared to Other Valves

Stainless steel ball valves have emerged as a preferred choice in plumbing systems due to their unique advantages over traditional valve types like gate and globe valves. One of the key features that set them apart is their robust construction, which offers superior corrosion resistance. According to a report by the International Journal of Industrial Chemistry, stainless steel can withstand varied environmental conditions, making it an ideal material for plumbing applications that involve exposure to moisture and corrosive substances. This durability not only extends the life of the valves but also reduces maintenance costs significantly.

In terms of functionality, stainless steel ball valves are known for their excellent flow control characteristics. Their design allows for quick opening and closing, with only a quarter turn needed to operate fully. This efficiency translates into lower pressure drops within piping systems, which can optimize performance. The American Society of Mechanical Engineers (ASME) states that high-performance ball valves can achieve a flow coefficient (Cv) that is up to 50% higher than that of comparable gate valves under similar conditions. This increased flow capability underlines the efficiency of stainless steel ball valves, making them especially suitable for applications requiring rapid flow and minimal turbulence.

Moreover, the sealed design of these valves prevents leaks, which is crucial for maintaining system integrity. Reports from the Valve Manufacturers Association indicate that nearly 40% of valve failures in plumbing systems are due to leaking seals, highlighting the importance of utilizing reliable valve designs. With their unique combination of strength, efficiency, and leak-proof performance, stainless steel ball valves prove to be a superior option for modern plumbing requirements.

How Stainless Steel Ball Valves Improve Water Flow Efficiency

Stainless steel ball valves have become a preferred choice in plumbing systems due to their ability to significantly enhance water flow efficiency. According to a report by the American Society of Plumbing Engineers (ASPE), the use of ball valves in plumbing applications can reduce pressure drops by up to 80% compared to traditional gate or globe valves. This efficiency is largely attributed to the valve's design, which features a spherical closure element that provides a straight-through flow path, minimizing turbulence and friction.

Moreover, stainless steel ball valves are known for their durability and resistance to corrosion, making them suitable for a variety of environments, including both residential and commercial settings. In a study published in the Journal of Water Resources, researchers found that the lifespan of stainless steel valves can exceed 20 years, even when exposed to harsh water conditions. This longevity not only leads to lower maintenance costs but also ensures sustained water flow efficiency over time. Consequently, choosing stainless steel ball valves can be a strategic decision for plumbing systems aiming for reduced operational costs and improved performance.

Maintenance Tips for Long-lasting Performance of Stainless Steel Ball Valves

Stainless steel ball valves are a popular choice in plumbing due to their durability and resistance to corrosion. However, to ensure their longevity and optimal performance, regular maintenance is essential. Industry standards emphasize that routine inspections can extend the life of these valves significantly. According to recent industry data, well-maintained stainless steel ball valves can last up to 25 years, compared to an average lifespan of 10 to 15 years for those that receive little to no maintenance.

To maintain stainless steel ball valves effectively, operators should implement periodic checks that include examining seals for wear and ensuring that the valve opens and closes smoothly. Lubricating the valve components, particularly the stem, with suitable oils can enhance their functioning and prevent seizing. Furthermore, keeping the valves clean and free from debris is crucial, as even minor particles can affect their operation. Reports indicate that valves that undergo regular maintenance reduce the risk of leaks by as much as 50%, ultimately saving costs and ensuring system reliability.

Why Choose Stainless Steel Ball Valves for Your Plumbing Needs - Maintenance Tips for Long-lasting Performance of Stainless Steel Ball Valves

| Feature | Benefits | Maintenance Tips |

|---|---|---|

| Corrosion Resistance | Durable and long-lasting performance in harsh environments. | Regularly inspect for any signs of wear or damage. |

| Easy Operation | Quick open/close operation helps in efficient plumbing management. | Lubricate valve stem and handles periodically to ensure smooth functionality. |

| Versatility | Suitable for a wide range of applications, including water, gas, and oil. | Keep valves clean and free from debris to maintain optimal performance. |

| Cost-Effectiveness | Long-term savings due to low maintenance and high durability. | Check and replace seals and gaskets if leaking occurs. |

| Safety Features | Minimized risk of leaks and burst pipes. | Conduct pressure tests periodically to ensure integrity under load. |

Applications of Stainless Steel Ball Valves in Residential and Industrial Plumbing

Stainless steel ball valves are increasingly favored in both residential and industrial plumbing due to their durability, corrosion resistance, and ease of operation. In residential plumbing, these valves are ideal for water supply systems, radiant heating, and gas lines. According to the International Association of Plumbing and Mechanical Officials, the use of stainless steel components can extend the lifespan of plumbing systems by up to 40%, reducing maintenance costs and ensuring the safe delivery of water and gas.

In industrial applications, stainless steel ball valves play a crucial role in processes involving chemicals, oil, and gas. The World Steel Association reports that stainless steel's resistance to extreme temperatures and pressures makes it suitable for handling hazardous materials. This compatibility is particularly important in industries like oil refining and pharmaceuticals, where the integrity of the plumbing systems directly impacts safety and efficiency. Additionally, stainless steel ball valves provide a reliable means of regulating flow, minimizing leakage incidents, and enhancing operational control in complex industrial setups.

Related Posts

-

Top Strategies for Maximizing the Efficiency of Pressure Relief Valves

-

The Ultimate Guide to Choosing the Perfect Heavy Duty Hose Reel for Your Gardening Needs

-

15 Best Tips for Choosing the Right Brass Fittings for Your Project

-

Exploring Innovative Alternatives to Traditional Pressure Gauges in Industrial Applications

-

Top 10 Pressure Washer Hose Reels for Efficient Cleaning in 2023

-

The Ultimate Guide to Choosing a Commercial Hose Reel for Optimal Efficiency and Durability