How to Choose the Right Pressure Gauge for Your Industrial Applications

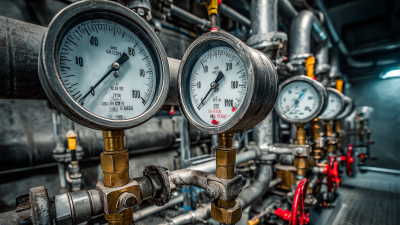

Selecting the appropriate pressure gauges for industrial applications is essential for ensuring safety, efficiency, and accuracy. According to a report by MarketsandMarkets, the global pressure gauge market is expected to grow from $3.3 billion in 2020 to $4.54 billion by 2025, indicating a significant demand for reliable measurement instruments across various sectors, including oil and gas, manufacturing, and pharmaceuticals. Pressure gauges play a crucial role in monitoring process variables, providing critical data that can prevent equipment failure and enhance operational performance. With a variety of types available, from mechanical to digital gauges, choosing the right one necessitates a thorough understanding of the specific requirements of your application, including pressure range, environment, and compatibility with different fluids. This guide aims to provide essential insights and considerations for selecting the most suitable pressure gauge for your industrial needs.

Selecting Pressure Gauges: Key Factors for Industrial Accuracy

When selecting pressure gauges for industrial applications, several key factors must be taken into consideration to ensure accuracy and reliability. The type of pressure gauge—absolute, gauge, differential, or multivariable—should be aligned with the specific requirements of the process. For instance, absolute pressure gauges are ideal for applications where reference to a vacuum is crucial, while gauge types measure pressure relative to atmospheric pressure, making them suitable for most standard applications.

Additionally, environmental conditions and the medium being measured also play a vital role in selecting the appropriate pressure gauge. Factors such as temperature, humidity, and the presence of corrosive substances can affect the performance and longevity of the gauge. Therefore, it is essential to choose a gauge crafted from materials that can withstand the specific conditions of the application. Regular calibration and maintenance are equally vital to ensure ongoing accuracy and to mitigate any potential risks associated with pressure measurement in industrial settings.

Understanding Different Types of Pressure Gauges for Specific Applications

When selecting a pressure gauge for industrial applications, it's crucial to understand the various types available, as each serves specific needs. Mechanical gauges, such as Bourdon tube gauges, are commonly used due to their simplicity and reliability. These gauges are ideal for applications requiring basic pressure measurement in a variety of environments, making them suitable for water, oil, and gas systems.

On the other hand, electronic pressure gauges offer higher accuracy and additional features, such as data logging and remote monitoring. These gauges are especially beneficial in applications where precision is paramount, such as in laboratory settings or critical process control. Additionally, specialized gauges, like differential pressure gauges and vacuum gauges, cater to unique application demands, measuring pressure differences or negative pressure in various systems. By understanding these types, you can better choose the right pressure gauge that meets the specific requirements of your industrial applications.

How to Choose the Right Pressure Gauge for Your Industrial Applications

| Type of Pressure Gauge | Measurement Range | Accuracy | Best Applications | Installation Type |

|---|---|---|---|---|

| Bourdon Tube Gauge | 0-100 psi | ±2% full scale | General industrial applications | Mechanical |

| Digital Pressure Gauge | 0-400 psi | ±1% full scale | Hydraulic systems | Electronic |

| Diaphragm Pressure Gauge | 0-2000 psi | ±1.5% full scale | Corrosive liquids and gases | Mechanical |

| Piezoelectric Pressure Sensor | 0-5000 psi | ±0.5% full scale | Aerospace and automotive testing | Electronic |

| Liquid Filled Pressure Gauge | 0-150 psi | ±2% full scale | Vibrating environments | Mechanical |

Evaluating Gauge Range: Importance of Operating Pressure Variables

When selecting a pressure gauge for industrial applications, evaluating the gauge range based on operating pressure variables is crucial. The gauge must be capable of measuring the minimum to maximum pressure expected within the system to ensure both accuracy and safety. An improperly selected range can lead to malfunctions or inaccurate readings, which can potentially compromise the integrity of the entire system. For instance, a gauge with a range too narrow for high-pressure operations may become overburdened, while one with too wide a range may not provide the precision required for low-pressure measurements.

Moreover, it's essential to consider not only the static pressure but also fluctuations that may occur during operation. Understanding the normal operating conditions, such as pressure spikes or drops, allows for the selection of a gauge that can withstand these variations. Using a gauge with a range that exceeds the maximum operating pressure, typically recommended to be 1.5 times the expected maximum, provides a safety buffer. This ensures that the gauge remains functional and reliable, maintaining its accuracy over longer periods and making it a pivotal component of industrial monitoring and control systems.

Material Compatibility: Ensuring Longevity in Harsh Industrial Environments

When selecting a pressure gauge for industrial applications, material compatibility is a critical factor that directly influences the gauge's longevity and performance. In harsh environments, where exposure to corrosive substances, extreme temperatures, or abrasive particles is common, choosing the right materials helps to minimize wear and tear. For instance, stainless steel is often preferred for its resistance to corrosion and durability, making it suitable for a variety of fluids and gases. Additionally, gauges with diaphragms made of compatible synthetic materials can help ensure that the internal mechanisms remain intact over prolonged usage.

Another crucial aspect of material compatibility is the gauge's ability to accommodate specific process media. Depending on the chemicals involved, using gauges with PTFE or Monel components may be necessary to avoid chemical reactions that could compromise gauge integrity. It is vital to evaluate not only the immediate application conditions but also the potential future exposure to different substances. By thoroughly assessing material compatibility, industries can enhance the reliability of their pressure gauges, ensuring optimal performance and reducing maintenance costs in the long run.

Calibration and Maintenance: Best Practices for Reliable Pressure Measurement

Calibration and maintenance are critical components in ensuring reliable pressure measurement in industrial applications. Regular calibration of pressure gauges is essential to maintain accuracy. According to the National Institute of Standards and Technology (NIST), calibration should at least be performed annually or whenever there are significant changes in environment or usage conditions. This frequency helps to minimize measurement errors that could result in costly operational disturbances.

Tips: Consistent maintenance routines can greatly enhance gauge reliability. Consider implementing a standardized weekly inspection schedule to check for any signs of wear or damage. Additionally, always document calibration results and maintenance activities to identify patterns or recurring issues.

Moreover, proper storage of pressure gauges when not in use is vital. Exposure to extreme temperatures, vibrations, or corrosive environments can lead to inaccuracies in readings. The American Society for Quality (ASQ) highlights that maintaining a clean and controlled environment reduces the risk of contamination and extends the lifespan of measuring instruments.

Tips: Use protective casings or covers for gauges when not actively in use, ensuring they are stored in a climate-controlled area. Implement a quick visual check policy to easily catch any wear and tear before it leads to major calibration issues.

Related Posts

-

How to Choose the Right Pressure Gauges for Your Industrial Needs

-

Ultimate Pressure Gauges Procurement Checklist for Global Buyers

-

Exploring Innovative Alternatives to Traditional Pressure Gauges in Industrial Applications

-

Essential Checklist for Choosing the Right Sprayer Parts to Maximize Efficiency and Performance

-

Maximizing Efficiency: How Industrial Hose Reels Transform Your Workspace Productivity

-

Troubleshooting Common Issues with Hose Reels: Solutions You Need to Know