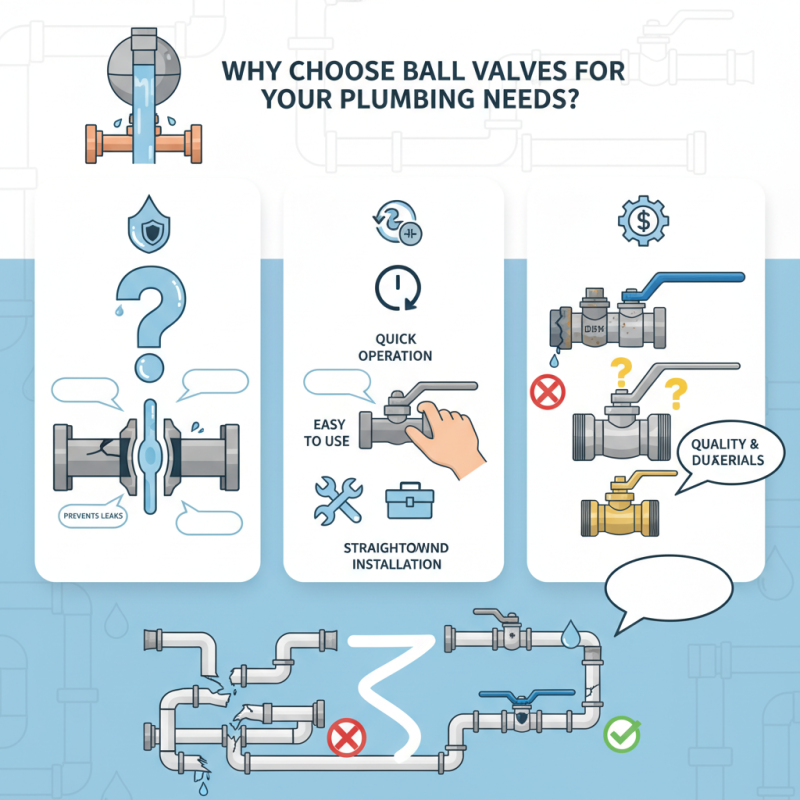

Why Choose Ball Valves for Your Plumbing Needs?

When it comes to plumbing, choosing the right valve can make a difference. Ball valves stand out for their reliability and ease of use. They offer a tight seal, preventing leaks and ensuring efficient water flow.

In many systems, ball valves are a popular choice. Their design allows for quick operation. You can turn them on or off with just a quarter turn. This simplicity makes installation straightforward, even for those who are not professionals. However, the wrong choice can lead to problems down the line.

It’s essential to consider quality when selecting ball valves. Not all options are created equal. Investing in durable materials can save you trouble later. In the end, while ball valves are effective, you must choose wisely to avoid future issues.

Benefits of Using Ball Valves in Plumbing Systems

Ball valves have become a popular choice for plumbing systems. Their design allows for quick and easy shut-off capabilities. This means reduced risk of leaks and more efficient water control. They can handle high pressure and temperature, making them versatile and reliable.

Tips: When choosing a ball valve, check the materials. Brass and stainless steel are durable options. Ensure the valve size matches your piping to avoid flow issues. Installation may seem straightforward, but improper fitting can lead to future leaks.

Another benefit is minimal maintenance. Ball valves typically require little attention once installed. This can save time and money in the long run. However, periodically inspecting them is wise. Signs of wear can lead to costly repairs if ignored.

Keep in mind that not all ball valves are created equal. It's essential to consider their intended use. Some designs may not perform well under specific conditions. This can affect your plumbing system's overall efficiency and safety.

How Ball Valves Work: A Mechanism Overview

Ball valves are popular in plumbing due to their efficient design. Their mechanism is simple yet effective. A rotating ball with a hole controls the flow of water. When the hole is aligned with the pipe, the flow is open. When rotated perpendicular, the flow stops.

According to a recent industry report, ball valves have a failure rate of less than 1% in standard applications. This is impressive compared to other valve types. They provide a reliable solution for both residential and commercial plumbing. However, improper installation can lead to issues. Over-tightening can damage the valve. Similarly, using them for inappropriate liquids may reduce their lifespan.

The ease of operation is another advantage. A quarter turn of the handle is often all that is needed. This quick action saves time and effort. Yet, it is important to regularly check and maintain these valves. Neglect can lead to leaks, which are problematic. Regular inspections are key to ensuring optimal performance, especially in high-pressure systems.

Comparing Ball Valves to Other Valve Types

When comparing ball valves to other valve types, a few key factors stand out. Ball valves are known for their durability and reliability. They can handle high-pressure situations better than many other valves, such as gate or globe valves. According to industry reports, ball valves can withstand pressures up to 6000 psi, while gate valves typically manage around 2500 psi. This makes ball valves a preferred choice for demanding applications.

Another critical aspect is flow control. Ball valves offer minimal pressure drop. They provide a full flow area, which reduces turbulence. In fact, studies show that ball valves can achieve a flow coefficient (Cv) of up to 400. In contrast, globe valves often have a Cv value below 100. This means less energy loss and better efficiency. However, ball valves can wear down their seals quicker when operated frequently. This can result in leakage if not regularly maintained.

Additionally, ease of operation plays a role. Ball valves require just a quarter-turn to open or close fully. This quick response can be crucial in emergency situations. Other valve types, like butterfly valves, may need multiple turns. Yet, the initial cost of ball valves can be higher than that of other types. It's essential to weigh these factors when choosing the right valve for your plumbing needs.

Common Applications of Ball Valves in Plumbing

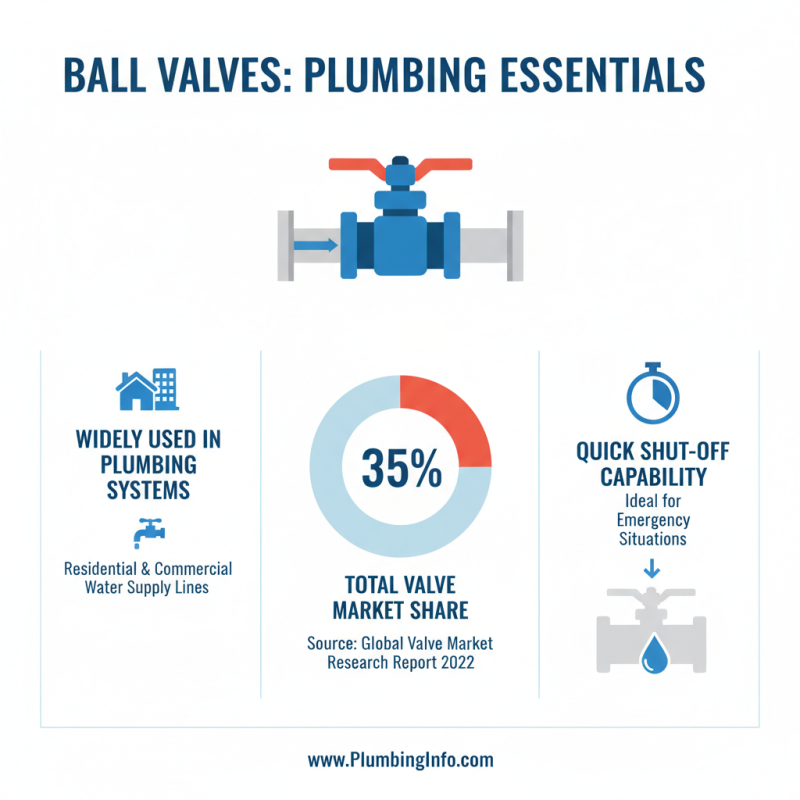

Ball valves are widely used in plumbing systems, showcasing their versatility across various applications. According to the Global Valve Market Research Report 2022, ball valves hold approximately 35% of the total valve market share, highlighting their importance. They are commonly found in residential and commercial settings, especially in water supply lines. Their ability to provide quick shut-off makes them ideal for emergency situations.

In industrial applications, ball valves play a critical role in controlling the flow of liquids and gases. They are often used in chemical processing plants, oil and gas facilities, and water treatment plants. A report by the Industrial Valve Market suggests that ball valves are favored for their durability and low resistance to fluid flow. This low resistance can improve efficiency, leading to significant cost savings over time.

Despite their many advantages, ball valves have some limitations. They may not perform well in throttling applications, leading to flow instability. Additionally, if improperly installed, they can be prone to leakage. Regular maintenance is crucial as wear and tear can reduce their effectiveness. Overall, while ball valves are essential, it's vital to assess their suitability for specific plumbing needs.

Maintenance Tips for Longevity of Ball Valves

Ball valves are popular for their durability and reliability. To ensure they last, proper maintenance is essential. Regular inspection helps catch minor issues before they escalate. Check for leaks around the valve body and connection points. Addressing these small problems promptly can save you from larger headaches later.

Cleaning is another crucial maintenance step. Debris can accumulate inside the ball valve, affecting its performance. Use a soft brush to clean the exterior regularly. Occasionally, you may need to disassemble the valve for a thorough cleaning. However, this task is best handled by someone with experience. Rushing this process can lead to mistakes that compromise the valve’s integrity.

Lubricating the valve stem aids in smooth operation. A light application of a petroleum-based lubricant can prevent seizing. Avoid over-lubricating, as excess lubricant may attract dirt. Periodic checks on the operating handle can ensure that it remains functional. If the handle feels stiff, examine it closely for any needed repairs. Regular maintenance tasks can seem tedious, yet they are vital for the longevity of your ball valves.

Related Posts

-

The Ultimate Guide to Choosing a Commercial Hose Reel for Optimal Efficiency and Durability

-

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Spray Nozzle for Your Needs

-

5 Best Strategies for Choosing the Right Hose Reel for Your Needs

-

Ultimate Pressure Gauges Procurement Checklist for Global Buyers

-

How to Choose the Right High Pressure Hose for Your Specific Applications

-

Top Air Hose Reel Types: Choosing the Best for Your Needs