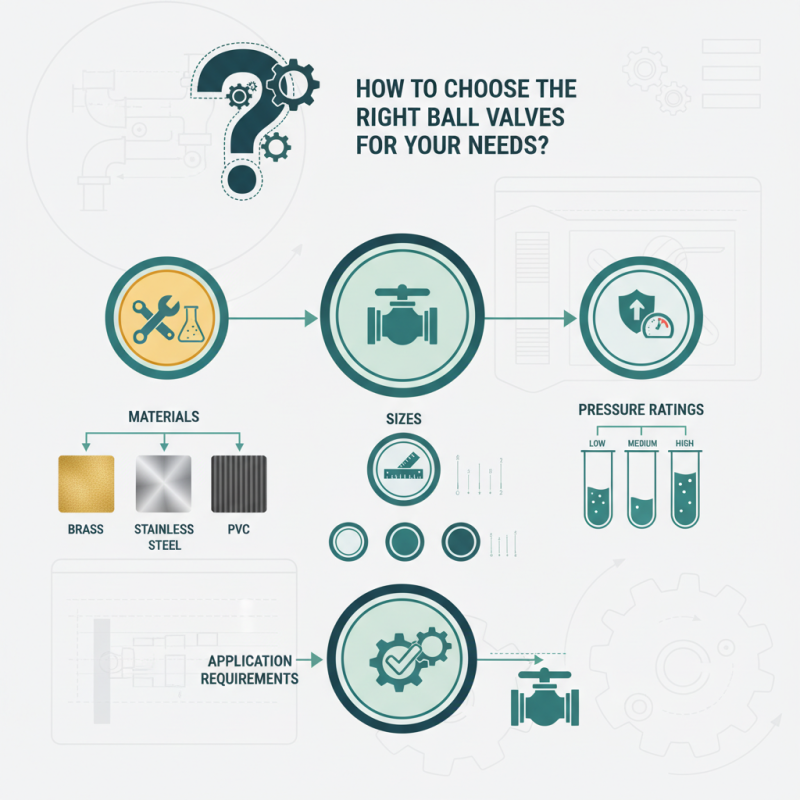

How to Choose the Right Ball Valves for Your Needs?

Choosing the right ball valves for your application can be challenging. The market is flooded with different types. Each serves unique functions and has specific features. Understanding these aspects is crucial for effective decision-making.

Ball valves are essential in many industries. They control the flow of liquids and gases. Their performance directly impacts the efficiency of your system. However, picking the wrong type might lead to leaks or failures. This can result in significant downtime and costly repairs.

Different materials, sizes, and pressure ratings exist. Each of these factors should align with your needs. For example, a valve made of brass may not withstand highly corrosive substances. Many overlook this detail, leading to dissatisfaction. Taking time to assess your requirements can make a difference.

Understanding the Basics of Ball Valves and Their Applications

Ball valves are crucial components in various industries, primarily due to their simplicity and reliability. They are designed to control the flow of liquids and gases. According to a recent industry report, the global ball valve market is projected to reach $9.75 billion by 2024, demonstrating their increasing importance. Their versatility allows them to be used in water treatment, chemical processing, and oil and gas applications.

When selecting ball valves, understanding their types is vital. There are floating ball and trunnion-mounted ball valves. Floating ball valves are cost-effective for lower pressure applications. In contrast, trunnion-mounted valves are essential for high-pressure operations. An expert study identified that nearly 70% of businesses favored trunnion-mounted designs for their durability in demanding environments.

Choosing the right ball valve requires careful consideration of these factors. Size, pressure rating, and material are critical aspects. Materials range from stainless steel to PVC, each suiting different operational needs. Improper selection can lead to leaks and failures. Hence, it's essential to evaluate all variables thoroughly. Minor oversights can result in major issues, emphasizing the need for informed decisions in valve selection.

How to Choose the Right Ball Valves for Your Needs?

| Type of Ball Valve | Key Features | Common Applications | Size Range (inches) | Material Options |

|---|---|---|---|---|

| Floating Ball Valve | Simple design, low cost, good for low-pressure systems | Water systems, oil and gas, HVAC | 1/2 to 12 | PVC, Brass, Stainless Steel |

| Trunnion Ball Valve | Suitable for high pressure, better sealing with larger sizes | Oil and gas drilling, water treatment, chemical processing | 2 to 24 | Carbon Steel, Stainless Steel, Alloy |

| V Ball Valve | Provides precise flow control, suitable for throttling | Pulp and paper, chemical service | 1 to 10 | PVC, Stainless Steel |

| Electric Ball Valve | Automated control, can be integrated into systems | Process control, automation systems | 1/2 to 12 | Bronze, Stainless Steel |

| Gas Ball Valve | Designed for gas applications, robust design | Natural gas, LP gas systems | 1 to 8 | Copper, Stainless Steel |

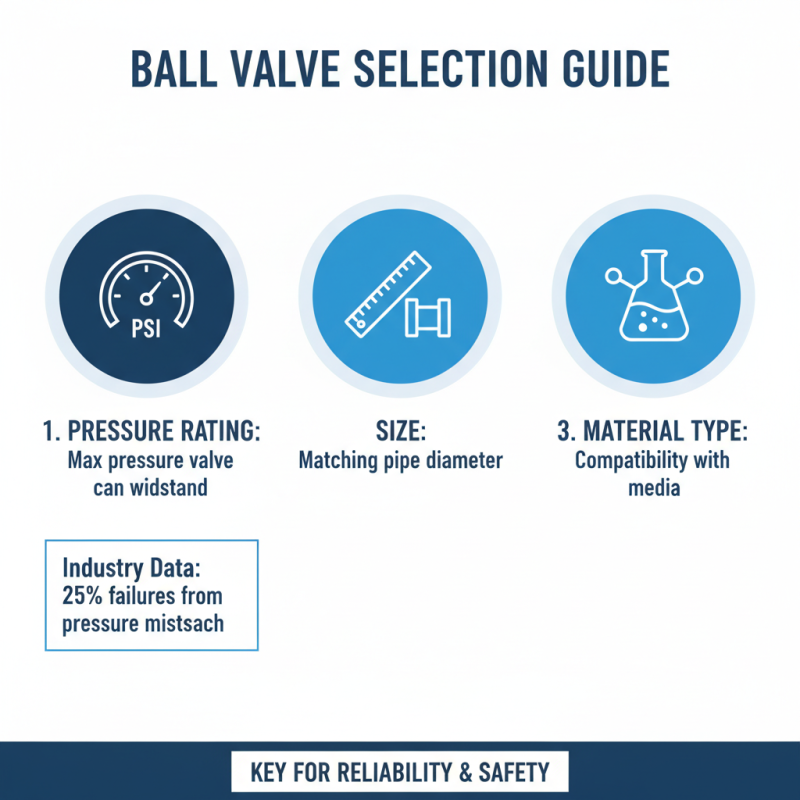

Identifying Key Specifications for Ball Valves Selection

When selecting ball valves, understanding key specifications is crucial. Focus on pressure ratings, size, and material types. The pressure rating indicates how much pressure the valve can withstand. Industry data shows that about 25% of valve failures occur due to pressure mismatches. Choosing a valve with the appropriate pressure rating is essential for reliability.

Size matters. A poorly sized valve can lead to inefficiencies. For instance, a valve too small can restrict flow, while one too large can decrease control. According to industry reports, correct sizing can improve energy efficiency by up to 15%.

Material selection also plays a vital role. Different applications may require valves made from various materials like stainless steel or plastic. Each material has its own set of advantages and drawbacks. For example, stainless steel offers durability but can be costlier. Understanding the specific environment is key. Whether it’s high-temperature applications or corrosive environments, the right material affects longevity and performance.

Evaluating Material Options for Various Environments

Choosing the right ball valves involves careful consideration of material options. Various environments require different materials to ensure durability and performance. For example, stainless steel is ideal for corrosive settings. It resists rust and maintains integrity in harsh conditions. On the other hand, PVC valves are suitable for chemical applications, offering lightweight and corrosion-resistant properties.

Tips for selecting the right material: Evaluate the temperature range. Certain materials may not withstand extreme heat or cold. Think about the medium being transported. Will it be abrasive? If so, stronger materials are necessary. Many overlook the importance of the right seal. A good seal can enhance performance and lifespan.

Some users may settle for quick decisions. This can lead to issues down the line, such as leaks or valve failure. Reflect on the environmental factors that could affect valve choice. Consider risk factors thoroughly. Balancing cost versus longevity is also vital. Investing in the right material now can save money later.

Considerations for Size and Pressure Ratings in Ball Valves

When selecting ball valves, size and pressure ratings are crucial. It’s important to match the valve to your system’s specifications. A study by the American Society of Mechanical Engineers notes that improper sizing can lead to system failures. Ball valves vary widely in size, typically ranging from 1/4 inch to 12 inches. Choosing the right size helps maintain optimal flow rates.

Pressure ratings also play a major role in performance. They are usually classified as ANSI or API ratings. For instance, ANSI Class 150 valves can handle pressures up to 285 PSI. Meanwhile, Class 300 valves can manage up to 740 PSI. An incorrect pressure rating can result in leaks or even catastrophic failures. Many industry reports highlight that 30% of operational failures occur due to mismatched ratings.

Remember, it’s not just about buying the largest or highest-rated valve. System requirements can change. Regular maintenance and inspection often reveal hidden issues. A valve that’s perfect today might not suit future needs. Each choice must reflect current and anticipated demands. Careful consideration yields better efficiency and safety in the long run.

Ball Valves Size and Pressure Ratings

This chart displays the relationship between the size of ball valves and their corresponding pressure ratings. Choosing the right ball valve depends significantly on these factors to ensure optimal performance in various applications.

Assessing Performance Features and Maintenance Requirements

When selecting ball valves, assessing performance features is crucial. Key factors include pressure ratings, size, and material. Studies show that 40% of valve failures are due to incorrect sizing. Valve sizes should match the pipe diameter. A mismatch can lead to inefficiencies and potential leaks.

Durability is equally important. For instance, valves made from stainless steel last longer in corrosive environments. Research indicates that using the right materials can extend valve life by up to 30%. However, many overlook maintenance needs. Regular inspection is often neglected. It can result in unexpected downtimes.

Only 15% of facilities follow a strict maintenance schedule. This oversight often leads to costly repairs and replacement. Proper maintenance can help identify issues early. Lubrication and system checks should be part of the routine. Even minor adjustments can ensure optimal performance. It's essential to reflect on these aspects during the selection process.

Related Posts

-

Why Choose Ball Valves for Your Plumbing Needs?

-

How to Choose the Right Pressure Gauges for Optimal Measurement Accuracy in Industrial Applications

-

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Spray Nozzle for Your Needs

-

2026 Best Hose Reel Options for Easy and Efficient Gardening?

-

Exploring Innovative Alternatives to Traditional Pressure Gauges in Industrial Applications

-

How to Choose the Right Electric Hose Reel for Your Needs