How to Choose the Right Pressure Gauges for Your Industrial Needs

Choosing the right pressure gauges for your industrial needs is a critical task that can significantly impact the efficiency and safety of your operations. Pressure gauges play a vital role in monitoring and controlling the pressure levels of gases and liquids within various systems. With a wide array of options available, from mechanical to digital gauges, understanding the specific requirements of your application is paramount.

Choosing the right pressure gauges for your industrial needs is a critical task that can significantly impact the efficiency and safety of your operations. Pressure gauges play a vital role in monitoring and controlling the pressure levels of gases and liquids within various systems. With a wide array of options available, from mechanical to digital gauges, understanding the specific requirements of your application is paramount.

Factors such as operating pressure range, accuracy, environment, and compatibility with various fluids come into play when selecting the most suitable gauge. This guide aims to provide you with key considerations and tips to help navigate the selection process, ensuring that you make informed choices that enhance performance while adhering to safety standards. By the end, you will be equipped with the knowledge to choose pressure gauges that meet both your operational and regulatory needs effectively.

Understanding Different Types of Pressure Gauges Available in the Market

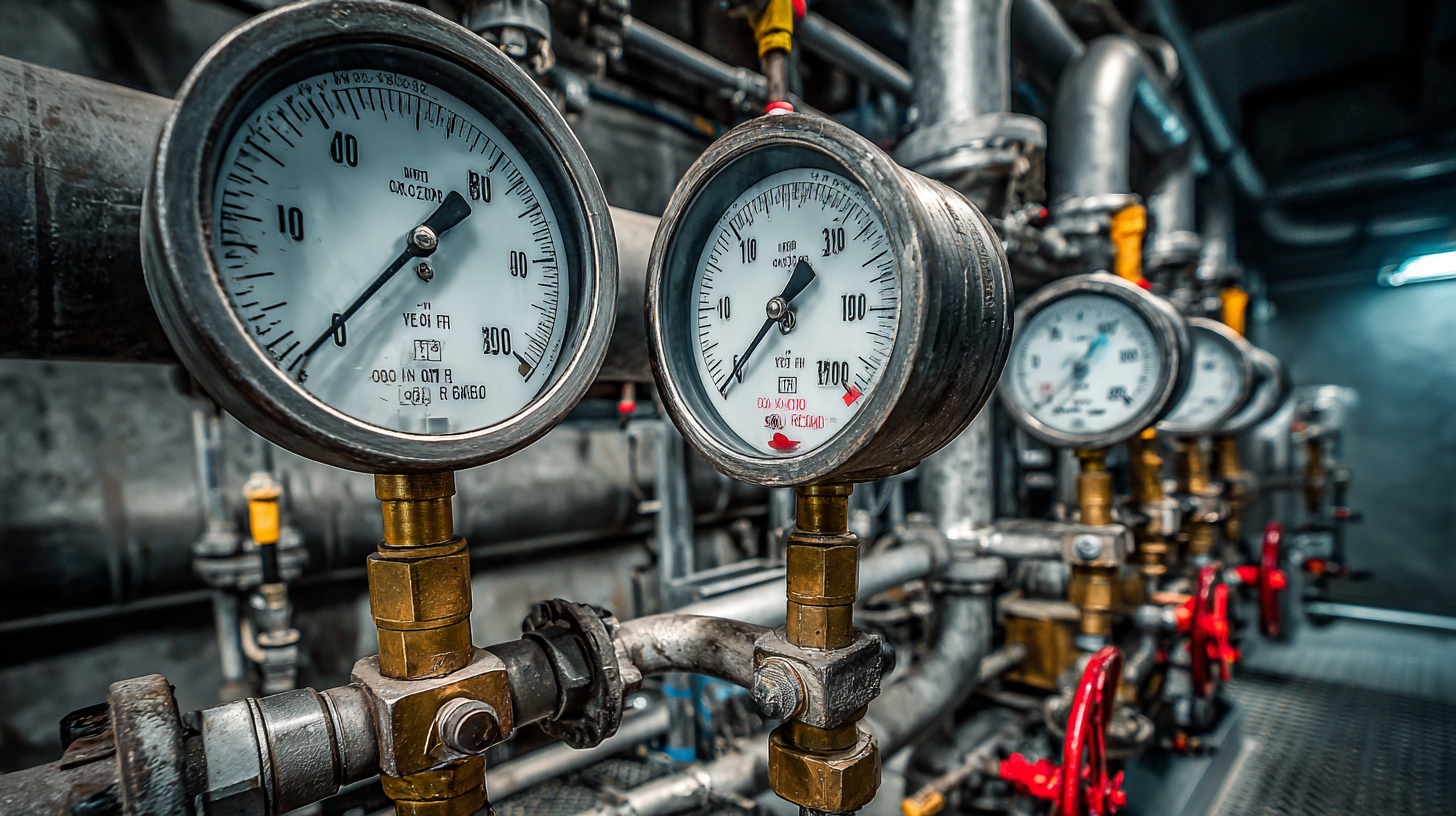

When selecting the appropriate pressure gauge for industrial applications, it's essential to understand the various types available in the market. Mechanical gauges, such as Bourdon tube and diaphragm gauges, are commonly used due to their reliability and simplicity.

Bourdon tube gauges function through a coiled tube that straightens under pressure, providing a reading on a dial. These gauges are ideal for general-purpose applications in less harsh environments.

Bourdon tube gauges function through a coiled tube that straightens under pressure, providing a reading on a dial. These gauges are ideal for general-purpose applications in less harsh environments.

In contrast, electronic pressure gauges offer greater accuracy and additional features. They utilize sensors that convert pressure changes into electrical signals, which can be displayed digitally. This type of gauge is particularly beneficial in high-precision applications where real-time data monitoring is crucial. Additionally, there are specialized gauges like absolute pressure gauges, which measure pressure relative to a perfect vacuum, and differential pressure gauges, which assess the difference between two pressure points. Understanding these types will help you choose the right gauge that meets your specific industrial requirements.

Key Factors to Consider When Selecting Pressure Gauges for Industrial Use

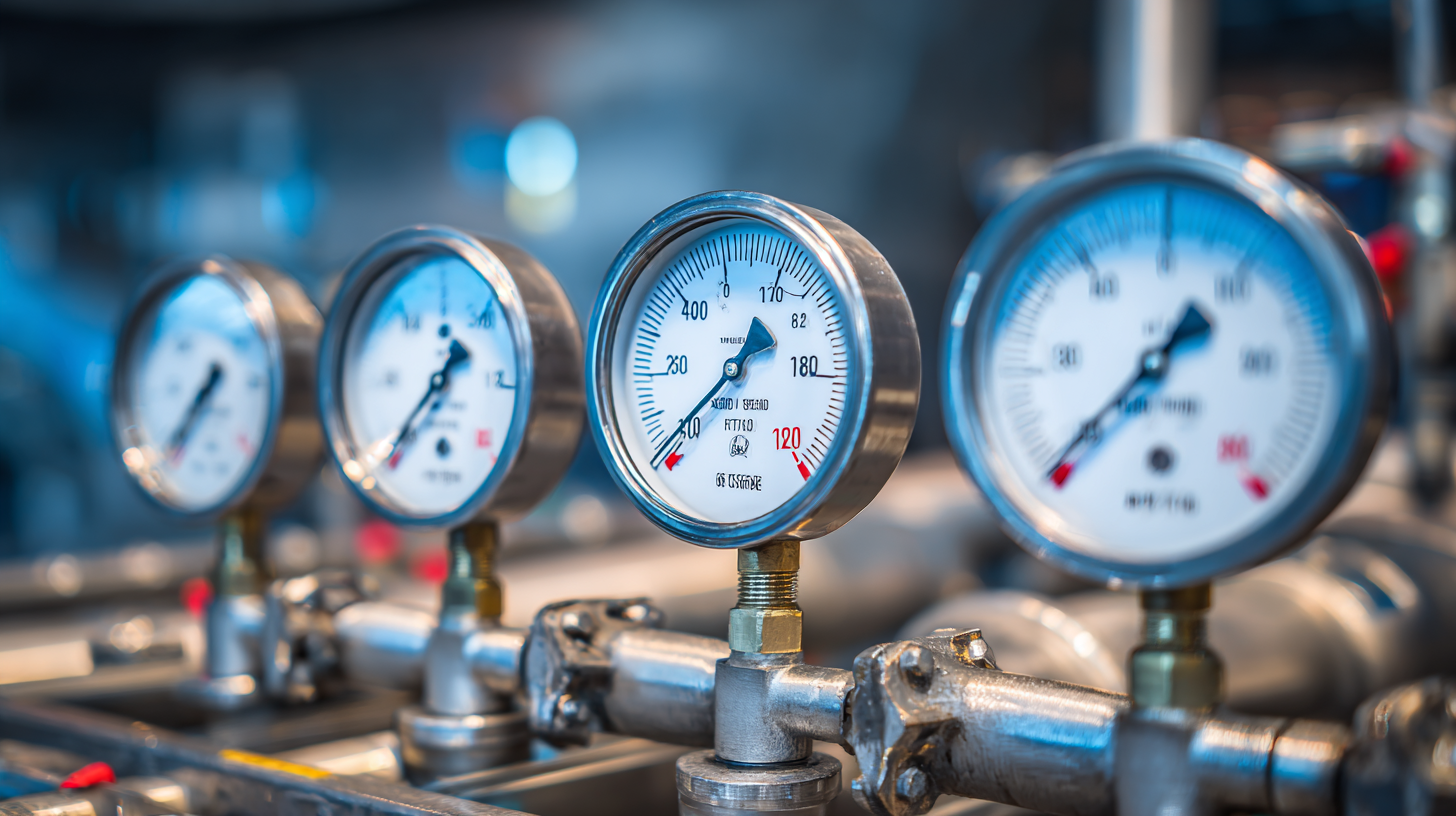

When selecting pressure gauges for industrial applications, several key factors come into play. Firstly, the gauge type—analog or digital—should be determined based on the needed accuracy and ease of reading. According to a recent industry study by the Instrumentation Society, digital gauges offer precision that can be critical in high-stakes environments, showcasing measurement accuracy of ±0.1%, which is crucial for processes requiring stringent control.

Another important consideration is the pressure range of the gauge. It’s essential to choose a gauge with a range that suits the specific application to avoid premature wear or damage. A report from TechSci Research indicates that inappropriate range selection can lead to operational inefficiencies and potential safety hazards, with nearly 30% of equipment failures attributed to incorrect gauge usage.

**Tips:** Always look for gauges that are compatible with the fluids involved; corrosive environments may necessitate stainless steel or ceramic options. Additionally, consider the ambient temperature and pressure fluctuations that the gauge will endure to ensure long-term reliability and performance.

Assessing Accuracy and Calibration Standards for Industrial Pressure Gauges

When selecting pressure gauges for industrial applications, it is imperative to assess their accuracy and calibration standards. Accurate pressure measurement is critical in various fields, from managing hypertension in healthcare to optimizing offshore gas production. The WHO emphasizes that precise blood pressure (BP) measurements can significantly impact health outcomes, making reliable calibration vital. Calibration not only ensures precision but also compliance with industry standards. According to industry reports, the global pressure transmitter market is projected to reach $3.84 billion by 2030, highlighting the increasing demand for accurate pressure measurement in various sectors.

In high-stakes environments such as offshore multiphase flow measurement and medical hemodynamic monitoring, even minor deviations can lead to significant consequences. For instance, studies have shown that pressure-induced temperature errors can adversely affect the assessment of ocean heat content, signaling the importance of rigorous calibration protocols. For industrial pressure gauges, choosing devices with accredited calibration services ensures that instruments maintain their efficacy, contributing to enhanced product quality and operational efficiency. By prioritizing accuracy and adhering to established calibration standards, industries can mitigate risks and improve reliability across applications.

How to Choose the Right Pressure Gauges for Your Industrial Needs

| Gauge Type | Accuracy (%) | Calibration Standard | Operating Range (psi) | Applications |

|---|---|---|---|---|

| Mechanical | ±1.5% | ISO 17025 | 0-300 | Oil and Gas, Water Treatment |

| Digital | ±0.5% | NIST | 0-1500 | Chemical Processing, Aerospace |

| Intrinsically Safe | ±1.0% | ATEX | 0-200 | Pharmaceutical, Oil and Gas |

| Differential | ±0.25% | ISO 9001 | -5 to 100 | HVAC, Automotive Testing |

| Compound Gauge | ±1.0% | ISO 17025 | -30 to 300 | Food & Beverage, Refrigeration |

Evaluating Environmental Conditions for Optimal Gauge Performance

When selecting the right pressure gauges for industrial applications, it's crucial to evaluate environmental conditions to ensure optimal performance. Factors such as temperature, humidity, and the presence of corrosive substances can significantly influence the functionality and lifespan of gauges. For instance, extreme temperatures can lead to measurement inaccuracies, while high humidity can facilitate corrosion, affecting gauge readings. Recent evaluations highlight that under varying environmental conditions, the accuracy of pressure gauges can fluctuate by up to 5%, underscoring the importance of thorough assessment before making a selection.

Tips: Always analyze the specific environmental factors your gauge will encounter. If your operational area features extreme weather fluctuations, consider choosing specialized gauges designed to withstand such conditions. For humid or corrosive environments, look for gauges made from materials specifically fortified against these challenges, such as stainless steel or other durable alloys.

Moreover, it’s beneficial to monitor continuously. Advanced IoT-based monitoring systems can provide real-time evaluations of gauge performance, enabling you to respond promptly to environmental changes. By harnessing technology, industries can improve their operational efficiency and reliability, aligning with emerging trends outlined in various studies evaluating how environmental parameters impact equipment performance across sectors.

Budgeting for Pressure Gauges: Cost vs. Quality Considerations

When selecting pressure gauges for industrial applications, budgeting is a critical factor that ultimately influences the quality and functionality of the equipment. A recent report indicates that many businesses are increasingly facing financial pressures, with projections suggesting that budget deficits in various sectors, including industrial manufacturing, may reach unprecedented levels. This scenario necessitates careful consideration of cost versus quality in sourcing pressure gauges. While opting for low-cost alternatives might provide immediate budget relief, these gauges can compromise accuracy and longevity, leading to increased maintenance costs.

Tips: Always prioritize quality measurements over initial costs. Investing in high-quality pressure gauges may reduce downtime and lower total ownership costs. Furthermore, consider the long-term reliability of the gauges, as cheaper options often require replacement sooner, negating any initial savings.

When budgeting for pressure gauges, it is essential to conduct thorough market research. Industry reports frequently highlight the correlation between investment in quality and operational efficiency. For instance, Jisc’s recommendations indicate that educational institutions benefit from strategic budgeting, implying similar results can be expected in industrial settings when investing in reliable instruments. Balancing cost considerations with the need for precision can lead to smarter procurement strategies, ultimately enhancing productivity while managing financial risks effectively.

Related Posts

-

Ultimate Pressure Gauges Procurement Checklist for Global Buyers

-

Exploring Innovative Alternatives to Traditional Pressure Gauges in Industrial Applications

-

How to Choose the Right Stainless Steel Fittings for Your Project

-

How to Choose the Right Electric Hose Reel for Your Industrial Needs Based on Key Performance Metrics

-

How to Choose the Right Stainless Steel Ball Valve for Your Project

-

10 Best Pressure Washer Hose Hacks for Ultimate Efficiency