How to Choose the Right Sprayer Parts for Optimal Performance

Choosing the right sprayer parts is essential for ensuring optimal performance of your spraying equipment. Whether you're a professional in agriculture, landscaping, or construction, understanding the specific components that make up your sprayer can greatly enhance its efficiency and lifespan. The right selection of sprayer parts not only maximizes the effectiveness of your spraying tasks but also minimizes downtime and maintenance costs.

With a plethora of options available in the market, it can be overwhelming to pinpoint the exact parts needed for your unique requirements. This guide aims to simplify the decision-making process by providing insightful tips and considerations to help you select the best sprayer parts that align with your operational needs. By equipping yourself with the right knowledge, you can ensure your sprayer operates at its best, delivering consistent results every time.

Understanding Different Types of Sprayers and Their Components for Performance

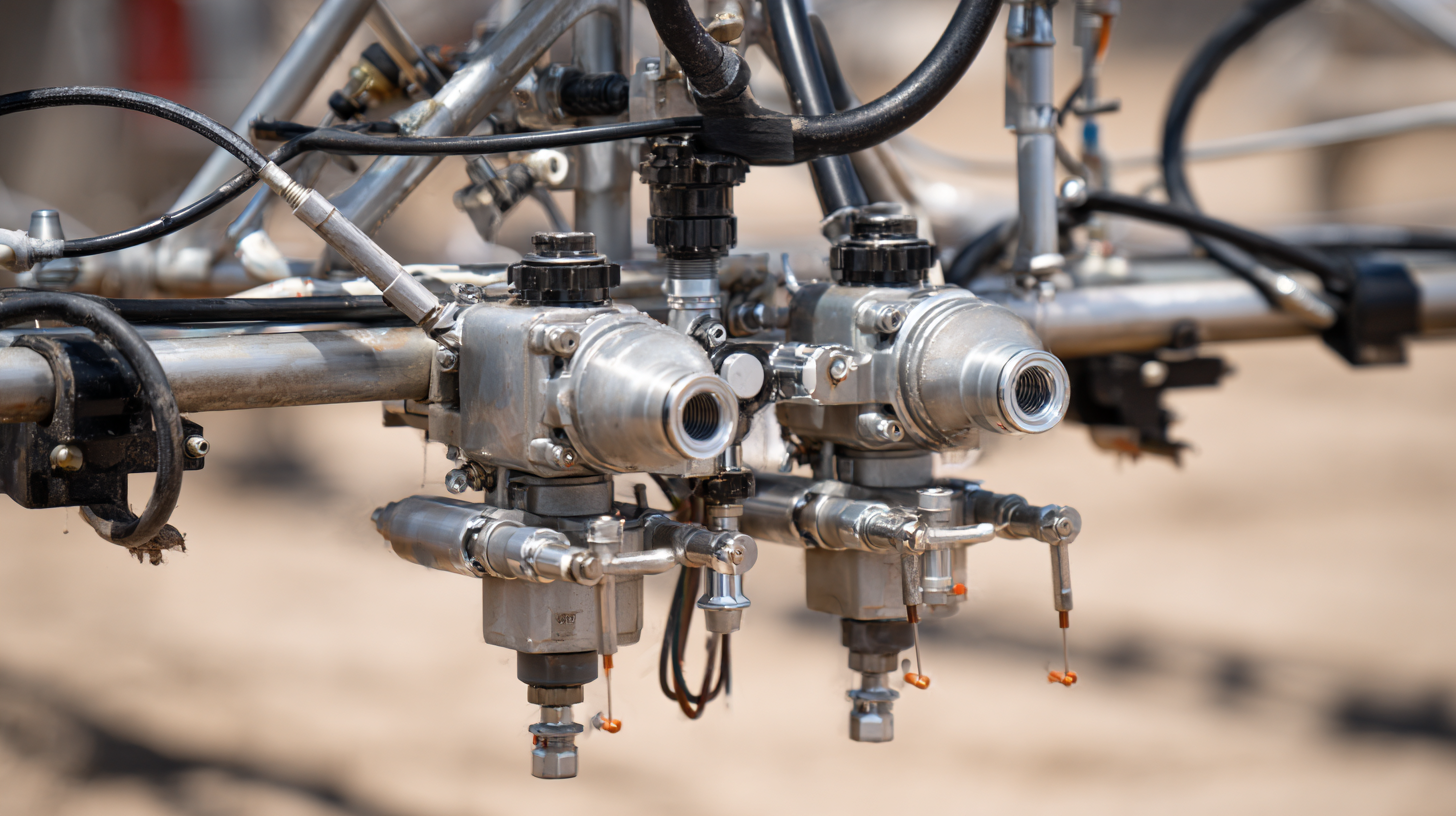

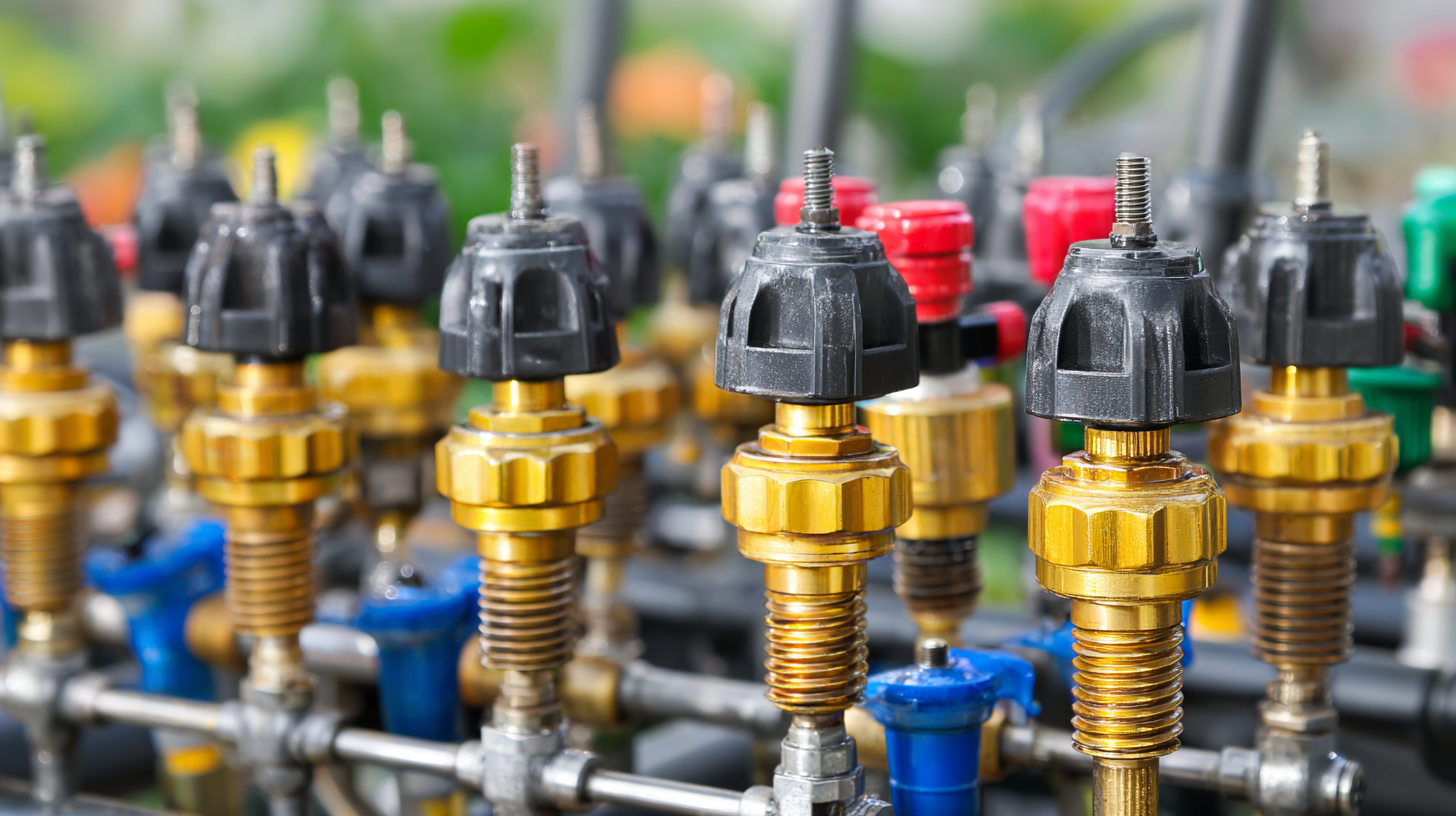

When selecting sprayer parts for optimal performance, it’s essential to understand the various types of sprayers and their components. Sprayers can be categorized into several types, such as backpack sprayers, hand-held sprayers, and motorized sprayers. Each type serves a specific purpose and has unique components, including pumps, nozzles, hoses, and tanks. For instance, backpack sprayers are ideal for small to medium-sized tasks, while motorized sprayers are better suited for larger areas, requiring more robust parts that can handle increased pressure and volume.

The choice of components is crucial for ensuring the efficiency and longevity of the sprayer. Pumps, for example, need to match the sprayer type and the chemical formulations being applied. Similarly, nozzles play a vital role in determining the spray pattern and droplet size, impacting coverage and effectiveness. Understanding the specific requirements of your spraying tasks will guide you in selecting the right parts, ultimately resulting in improved performance and better results in your application.

Performance Comparison of Different Types of Sprayers

Key Factors to Consider When Selecting Sprayer Parts for Efficiency

When selecting sprayer parts, efficiency hinges on several key factors. First and foremost, compatibility is essential. Choosing parts that are specifically designed for your sprayer model can significantly enhance performance. According to a report by the Sprayer Equipment Manufacturers Association, mismatched parts can reduce efficiency by up to 30%. Additionally, looking into the material and durability of the parts is crucial; components made from high-quality, corrosion-resistant materials can extend the lifespan of your sprayer and maintain optimal functionality over time.

Tip: Always refer to your sprayer’s manufacturer specifications to ensure compatibility when purchasing new parts.

Another important factor to consider is the size and capacity of the sprayer’s components. Selecting parts that accommodate the correct flow rates can optimize application efficiency. A study published in the Journal of Agricultural Engineering Research indicates that sprayers operating at their ideal flow rates can improve pesticide application effectiveness by 25%. Furthermore, choosing adjustable pressure regulators can help cater to varying field conditions, allowing for more precise control.

Tip: Regularly assess your sprayer's performance metrics, as this can guide your decisions on which parts may require upgrades to enhance overall efficiency.

The Importance of Material Compatibility in Sprayer Parts Selection

When selecting sprayer parts, material compatibility is a critical aspect that directly impacts optimal performance. Different liquids require specific materials to ensure effective application and prevent chemical reactions that can compromise both the equipment and the substances being sprayed. For instance, using metal parts with corrosive chemicals can lead to rust and deterioration, while certain plastics may not withstand high temperatures or aggressive solvents. Therefore, understanding the properties of the materials involved is essential for maintaining the integrity of the sprayer and ensuring effective operation.

When selecting sprayer parts, material compatibility is a critical aspect that directly impacts optimal performance. Different liquids require specific materials to ensure effective application and prevent chemical reactions that can compromise both the equipment and the substances being sprayed. For instance, using metal parts with corrosive chemicals can lead to rust and deterioration, while certain plastics may not withstand high temperatures or aggressive solvents. Therefore, understanding the properties of the materials involved is essential for maintaining the integrity of the sprayer and ensuring effective operation.

Moreover, the environment in which the sprayer operates also dictates material selection. An agricultural sprayer exposed to UV rays, moisture, and varying temperatures demands durable materials that resist degradation over time. Selecting the right combinations—such as polypropylene for acid solutions or stainless steel for water-based products—can enhance longevity and efficiency. Ultimately, prioritizing material compatibility not only ensures the reliability of the sprayer parts but also maximizes productivity by minimizing downtime and maintenance costs.

Analyzing Flow Rates and Pressure Ratings for Optimal Sprayer Performance

When selecting the right sprayer parts, understanding flow rates and pressure ratings is crucial for achieving optimal performance. Analyzing flow rates aids users in determining how much liquid the sprayer can move within a specific timeframe, which directly affects coverage and efficiency. For example, a hose-end sprayer with a flow rate of 2.5 GPM (gallons per minute) can effectively cover larger areas faster than one with a lower rate, making it suitable for extensive outdoor tasks.

Pressure ratings, measured in PSI (pounds per square inch), are equally important to ensure a sprayer delivers adequate force to penetrate foliage or surfaces. Recent studies emphasize that sprayers designed with adjustable pressure settings can optimize performance across various applications; for instance, a variable rate spraying drone offers a customized approach that enhances fluid application efficiency. Data indicates that optimizing pressure and flow together not only improves spray pattern uniformity but also minimizes overspray and reduces wasted chemicals, ideal for both agricultural and industrial uses. Such precise calibration of sprayer components can significantly impact productivity and sustainability efforts within the industry.

Common Maintenance Practices to Ensure Longevity of Sprayer Parts

When it comes to maintaining sprayer parts and ensuring their longevity, adopting common maintenance practices is essential for optimal performance. Regular cleaning after each use, especially post-application, prevents residue buildup that can impair functionality. According to industry standards, nearly 70% of sprayer failures can be attributed to inadequate maintenance practices, underscoring the need for a systematic approach. This includes inspecting seals and gaskets for wear and tear, as these components play a crucial role in maintaining pressure and preventing leaks.

Additionally, seasonal maintenance, particularly during low-use months, is vital. For example, manufacturers recommend thorough inspections in December and January, a period identified as prime for machinery upkeep. Applying these practices not only extends the life of sprayer parts but can also enhance efficiency. Reports indicate that operators who regularly maintain their equipment can achieve a 15-20% increase in application precision and reduce downtime significantly. Incorporating these maintenance strategies ensures that sprayers perform at their best, ultimately leading to better results in various applications, from agricultural settings to home improvement projects.

Related Posts

-

Essential Checklist for Choosing the Right Sprayer Parts to Maximize Efficiency and Performance

-

Exploring Eco-Friendly Alternatives to Soft Wash Pumps: Efficiency and Sustainability in Pressure Cleaning

-

10 Best Pressure Washer Hose Hacks for Ultimate Efficiency

-

How to Choose the Right Stainless Steel Fittings for Your Project

-

7 Key Advantages of Using a High Pressure Hose Reel in Your Operations

-

Ultimate Pressure Gauges Procurement Checklist for Global Buyers