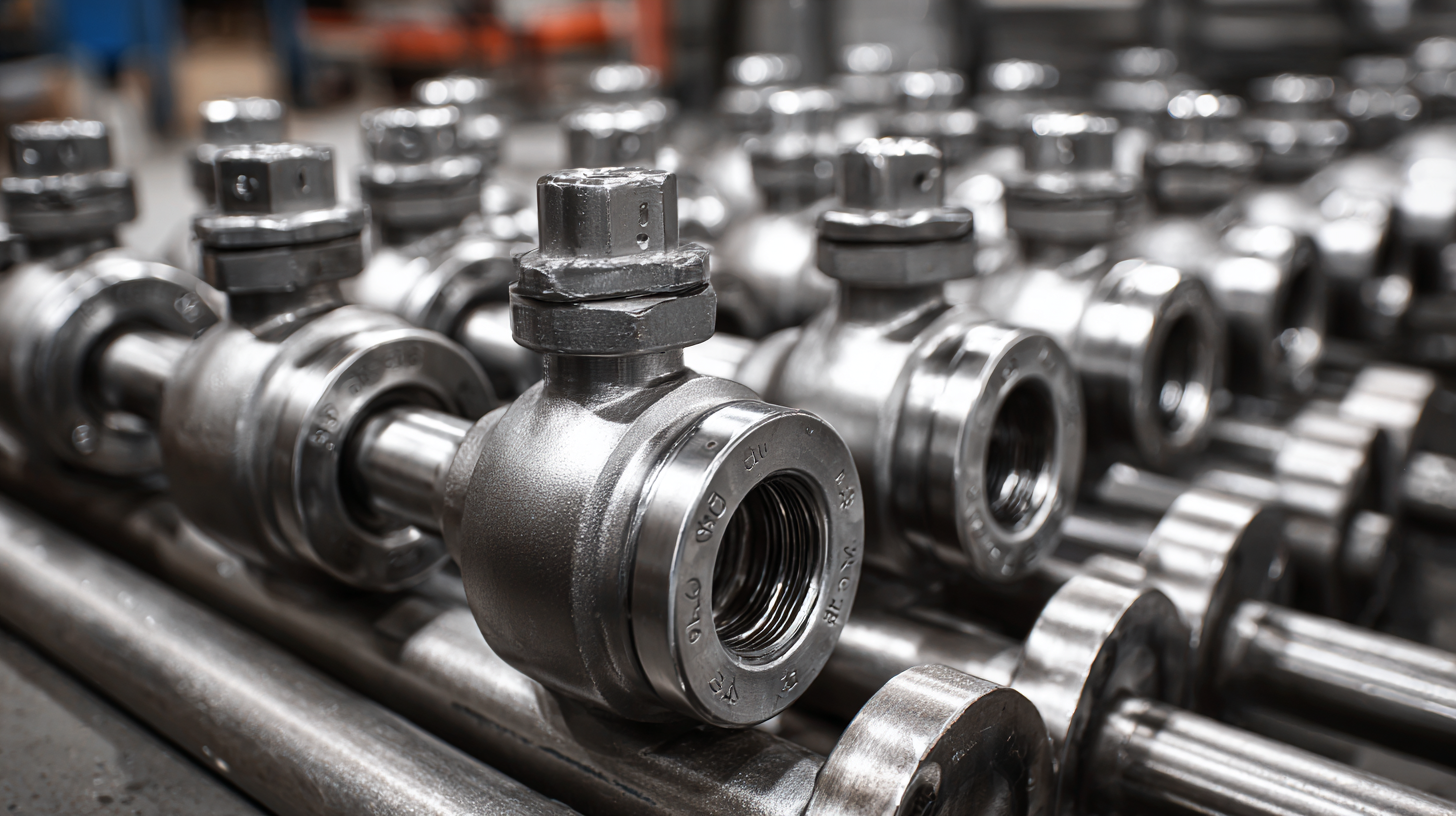

How to Choose the Right Stainless Steel Ball Valve for Your Project

Choosing the right stainless steel ball valve for your project is crucial for ensuring optimal performance and durability in your piping system. Stainless steel ball valves are renowned for their corrosion resistance, longevity, and reliability, making them a popular choice across various industries, including food and beverage, pharmaceuticals, and oil and gas.

However, with a multitude of options available on the market, selecting the most suitable valve can be a daunting task. Factors such as size, pressure rating, connection type, and the specific media being handled must all be considered carefully. In this guide, we will explore key considerations and best practices that will aid you in making an informed decision, ensuring that your stainless steel ball valve aligns perfectly with your project requirements, ultimately leading to enhanced efficiency and safety in your operations.

Understanding the Different Types of Stainless Steel Ball Valves Available

When selecting the right stainless steel ball valve for your project, understanding the different types available is crucial. There are three primary designs: full port, standard port, and reduced port ball valves. Full port valves allow for the same diameter flow as the pipe, which minimizes pressure loss and is ideal for high-flow applications. Standard port valves provide a good balance between flow efficiency and space, making them a versatile choice for general applications. Reduced port valves, on the other hand, have a smaller opening that reduces flow but can be beneficial in certain scenarios where pressure control is more critical than flow rate.

**Tips:** Consider the nature of the fluid you will be controlling, as some valves are better suited for specific media, including corrosive or high-temperature fluids. Additionally, the valve's end connections—be it threaded, welded, or flanged—should match your piping system to ensure compatibility.

Another essential factor is the valve's pressure rating. Make sure to select a valve that meets or exceeds the pressure requirements of your system. Also, don't forget to account for the installation environment. A valve resistant to corrosion and environmental factors will enhance longevity and reduce maintenance costs over time.

Key Factors to Consider for Selecting the Right Size and Pressure Rating

When selecting a stainless steel ball valve for your project, understanding the key factors of size and pressure rating is crucial. The correct size of the valve will directly affect its performance and efficiency in the system. To determine the appropriate valve size, you should consider the pipe diameter and the flow requirements of your application. A valve that is too small can restrict flow, leading to pressure drops and increased wear, while a valve that is too large may cause turbulence and inefficient operation. Therefore, evaluating the specifics of your piping system and the flow characteristics is essential in making the right choice.

In addition to size, the pressure rating of the stainless steel ball valve is another vital consideration. The pressure rating must match or exceed the maximum pressure that will be encountered in your application. This ensures the valve can withstand operational demands without failure, which is critical for maintaining system integrity and safety. Different materials and construction techniques affect the pressure rating, so always refer to the manufacturer's specifications. By carefully evaluating both size and pressure rating, you can select a stainless steel ball valve that will perform reliably in your project.

How to Choose the Right Stainless Steel Ball Valve for Your Project - Key Factors to Consider for Selecting the Right Size and Pressure Rating

| Valve Size (inches) | Pressure Rating (PSI) | Body Material | Temperature Rating (°F) | End Connection Type |

|---|---|---|---|---|

| 1/2 | 1500 | 304 Stainless Steel | -20 to 300 | Threaded |

| 3/4 | 1000 | 316 Stainless Steel | -20 to 400 | Flanged |

| 1 | 600 | 304 Stainless Steel | -20 to 300 | Welded |

| 1 1/4 | 1500 | 316L Stainless Steel | -20 to 450 | Threaded |

| 1 1/2 | 600 | 304 Stainless Steel | -20 to 300 | Flanged |

| 2 | 300 | 316 Stainless Steel | -20 to 350 | Welded |

Material Compatibility: Ensuring Optimal Performance in Your System

When selecting a stainless steel ball valve for your project, understanding material compatibility is crucial to ensuring optimal performance within your system. Different environments and fluid types can significantly impact the integrity and functionality of the valve. For instance, if your system experiences high temperatures or corrosive substances, it’s essential to choose a valve that can withstand these conditions without compromising performance. Stainless steel, known for its durability and resistance to oxidation, is often the go-to material, yet it’s vital to consider its specific grade and treatment based on the application.

**Tips**: Always check the chemical compatibility of the valve material with the fluids it will handle. Utilize resources such as compatibility charts or consult manufacturers to verify that your selected valve can endure the chemical properties of your media. Additionally, consider the temperature range and pressure levels of your system. Using valves rated for higher pressure can add an extra layer of safety and longevity.

Furthermore, the design of the ball valve itself plays a role in material compatibility. Some designs feature additional coatings or linings that enhance their resistance to chemical attack. When in doubt, collaborating with a manufacturer knowledgeable in valve applications can help you choose the perfect solution tailored to the specific needs of your project, ensuring seamless integration and reliable operation over time.

Material Compatibility of Stainless Steel Ball Valves

Evaluating Valve Features: Automation vs. Manual Operation

When selecting a stainless steel ball valve for your project, one crucial consideration is the mode of operation: automation versus manual control. Automated ball valves are ideal for applications requiring consistent and precise control, particularly in larger or more complex systems. They often come equipped with actuators that allow for remote operation, making them suitable for processes where safety and efficiency are paramount. These valves facilitate integration with control systems, enhancing operational efficiency and reducing the likelihood of human error.

On the other hand, manual ball valves offer simplicity and reliability, making them a popular choice for smaller or less frequent operations. They provide operators with tactile feedback and control, allowing for immediate adjustments based on real-time observations. In environments where quick changes are expected and automation is unwarranted, manual operation can be advantageous. Ultimately, the choice between automated and manual operation should align with the specific needs of your project, considering the factors of operational frequency, control precision, and overall system design.

Assessing Quality Standards and Certifications for Durability and Reliability

When selecting a stainless steel ball valve for your project, understanding the quality standards and certifications is crucial for ensuring durability and reliability. Stainless steel valves are typically assessed based on their compliance with various industry standards, such as ASTM A351 for castings and ASME B16.34 for valves. These certifications ensure that the valves can withstand high pressures and temperatures prevalent in industrial applications.

Moreover, the reliability of a ball valve is often correlated with its material specifications. For instance, valves made from 316 stainless steel are known for their excellent corrosion resistance and ability to perform in harsh environments. According to a report by the Industrial Valve Market Analysis, the demand for high-performance valves, particularly in the oil and gas sector, is expected to rise by 5.3% annually through 2027. Ensuring compliance with quality certifications such as ISO 9001 can further enhance a valve's credibility, as this certification signifies a commitment to consistent quality management processes.

In addition, third-party testing and certifications, like those offered by the American Society for Testing and Materials (ASTM), provide verification of performance under various conditions. Selecting valves with robust certifications ensures that your project is backed by reliable products, reducing the risk of failure and maintenance costs in the long run.

Related Posts

-

10 Best Pressure Washer Hose Hacks for Ultimate Efficiency

-

Ultimate Pressure Gauges Procurement Checklist for Global Buyers

-

7 Proven Tips for Finding the Best High Pressure Hose for Your Needs

-

How to Choose the Right Electric Hose Reel for Your Needs

-

The Definitive Ultimate Guide to Pressure Regulators: Unlocking Consistent Performance and Efficiency

-

How to Choose the Right Electric Hose Reel for Your Industrial Needs Based on Key Performance Metrics