How to Choose the Right Electric Hose Reel for Your Industrial Needs Based on Key Performance Metrics

In today's industrial landscape, the demand for efficient and effective tools is higher than ever, particularly when it comes to managing hoses for fluid distribution. An electric hose reel stands out as an essential piece of equipment in various industries, from construction to manufacturing, where the need for mobility and safety is paramount. According to a recent market analysis report by Grand View Research, the global market for hose reels is projected to reach $1.5 billion by 2025, growing at a CAGR of 4.5%. This surge is largely driven by the increasing automation of industrial processes and the rising importance of workplace safety. When choosing the right electric hose reel, it is crucial to consider key performance metrics such as durability, ease of use, and compatibility with existing systems. Making an informed decision can significantly enhance operational efficiency and safety standards in any industrial setting.

Key Performance Metrics to Consider When Selecting an Electric Hose Reel

When selecting an electric hose reel for industrial applications, several key performance metrics must be considered to ensure optimal functionality. Firstly, the hose capacity is crucial; many electric hose reels can handle hoses ranging from 50 to 200 feet, with a recommended diameter of 1/2 inch to ensure adequate flow rates. According to a 2022 report by the Industrial Hose Manufacturers Association, selecting a hose reel that matches your hose's specific needs can improve operational efficiency by up to 30%.

Another important metric is the retraction speed, which can significantly impact productivity. The average retraction speed for electric hose reels is typically between 10 to 15 seconds per 50 feet of hose. This speed facilitates quicker storage and minimizes downtime. Additionally, consider the reel’s durability and construction material; heavy-duty steel or high-strength plastic can withstand harsh industrial environments, prolonging the lifespan of your equipment. A durability study conducted by the Equipment Reliability Institute in 2023 showed that reels built with reinforced materials outperformed standard models by reducing failure rates by 40% in demanding settings.

Understanding Different Hose Reel Types for Industrial Applications

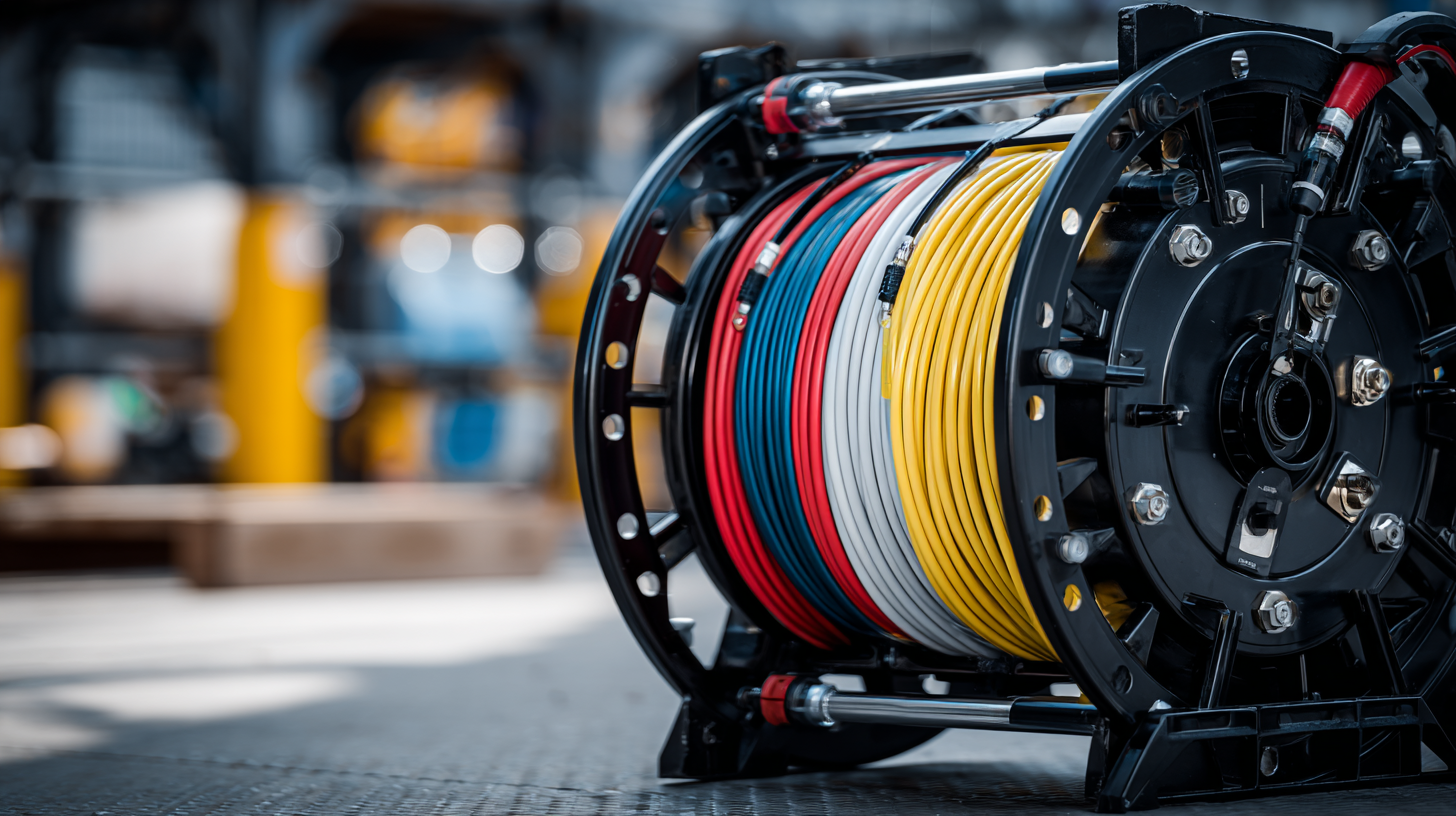

When selecting an electric hose reel for industrial applications, understanding the various types available is essential. There are primarily three types of electric hose reels: spring-driven, motorized, and manual retractable. Spring-driven hose reels are often favored for their ease of use and are ideal for environments requiring swift access, with a retraction mechanism powered by a rotary spring. In contrast, motorized hose reels, which can be controlled with the push of a button, offer better efficiency and safety in heavy-duty applications. According to market reports, the global electric hose reel market is projected to reach USD 1.2 billion by 2024, emphasizing the rapid growth of automated solutions in industrial sectors.

Furthermore, the choice of a hose reel should also consider the materials used for construction and the operational environment. For instance, steel reels are best suited for rugged conditions, whereas lightweight aluminum reels are perfect for portability. A study conducted by the Industrial Hose Association indicated that 65% of industrial facilities experienced improved workflow efficiency after switching to electric hose reels. These metrics highlight the benefits of selecting the right type of hose reel that aligns with operational needs and enhances overall productivity.

Evaluating Durability and Build Quality for Long-Term Use

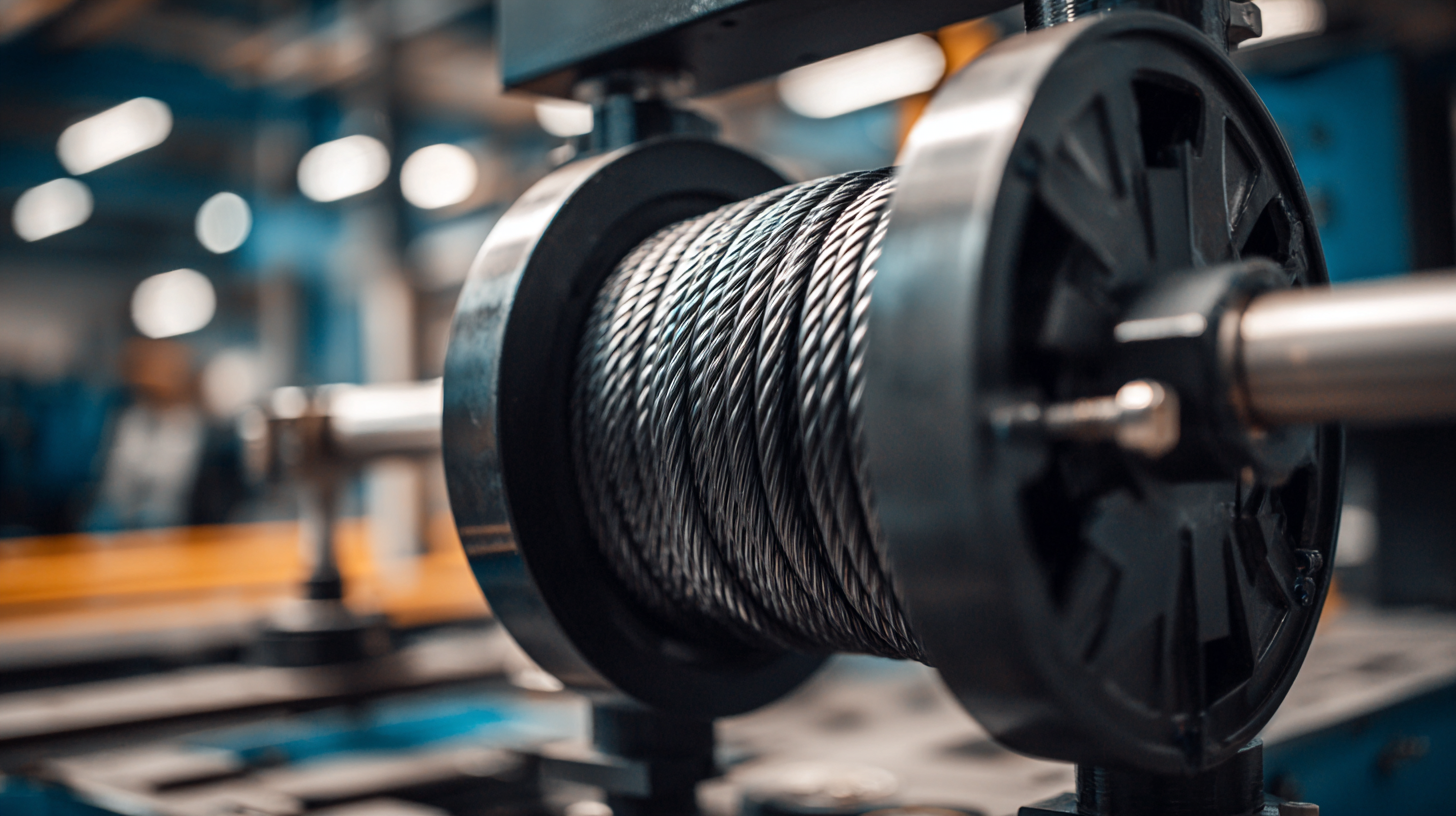

When selecting an electric hose reel for industrial applications, evaluating durability and build quality is paramount. Industrial environments often present demanding conditions, including exposure to harsh weather, chemicals, and heavy usage. A hose reel constructed from robust materials, such as high-grade steel or heavy-duty plastic, is essential to ensure it withstands these challenges. Features like corrosion resistance and UV protection can significantly extend the lifespan of your hose reel, making it a worthwhile investment for any business looking to reduce maintenance costs and downtime.

Another critical aspect of durability is the design of the reel itself. Look for features like reinforced mounting brackets and solid axle assemblies that provide stability and strength during operation. The efficiency of the rewind mechanism is also important; a reliable automatic or manual rewind should operate smoothly without jamming or excessive wear. By focusing on these key performance metrics, businesses can select a hose reel that not only meets their immediate needs but also offers long-term reliability and performance, ensuring a continuous workflow in demanding industrial settings.

Assessing Power and Voltage Requirements for Optimal Performance

When selecting the right electric hose reel for your industrial needs, understanding power and voltage requirements is crucial for achieving optimal performance. A well-chosen hose reel must align with your machinery's specifications, ensuring efficient operation without any risk of electrical overload. Pay attention to the power source—whether it’s a 120V or 240V system—this will significantly impact the effectiveness and longevity of the hose reel.

**Tip:** Always check the wattage ratings and ensure that the electric hose reel can handle the cumulative power draw of the tools you plan to use. This is especially important in high-demand environments where multiple tools run simultaneously.

Another key consideration is the type of application for which the hose reel will be used. If your environment requires frequent movement or high water flow rates, opting for a reel with higher voltage and amperage ratings will help maintain consistent performance without interruptions.

**Tip:** Look for models with adjustable voltage settings or built-in overload protection. This feature can provide additional safety and flexibility in various applications, making your operations smoother and reducing the risk of equipment damage.

Electric Hose Reel Power and Voltage Requirements

Comparing Price and Value: Finding the Best Electric Hose Reel for Your Budget

When selecting an electric hose reel for your industrial applications, understanding the balance between price and value is crucial. While it might be tempting to choose the least expensive option, it’s essential to evaluate the long-term benefits that different models provide. Factors such as durability, ease of use, and maintenance cost can significantly impact your overall investment. A higher upfront cost could translate into greater reliability and less downtime, thereby enhancing productivity in the long run.

To make an informed decision, consider the specific features that meet your operational needs. Look for reels that offer robust construction, adjustable rewinding speeds, and adequate hose capacity. Additionally, units equipped with safety features can prevent accidents and reduce liability costs. Researching customer reviews and seeking recommendations can further guide your selection process, ensuring that you find an electric hose reel that not only fits your budget but also meets your performance expectations. Taking the time to compare various options will ultimately help you make a smart investment that transcends initial price considerations.

Related Posts

-

7 Key Advantages of Using a High Pressure Hose Reel in Your Operations

-

Ultimate Guide to Choosing the Right Pressure Washer Hose for Your Cleaning Needs

-

5 Best Strategies for Choosing the Right Hose Reel for Your Needs

-

Troubleshooting Common Issues with Hose Reels: Solutions You Need to Know

-

Essential Checklist for Choosing the Right Sprayer Parts to Maximize Efficiency and Performance

-

Top Strategies for Maximizing the Efficiency of Pressure Relief Valves