How to Choose the Right High Pressure Hose for Your Specific Applications

In the industrial landscape, the selection of the appropriate high pressure hose is crucial for ensuring operational efficiency and safety. As indicated by the Fluid Power Journal, the global market for high pressure hoses is projected to grow at a CAGR of 6.1% from 2020 to 2025, driven largely by the rising demand in sectors such as construction, oil and gas, and manufacturing. A reliable high pressure hose must not only withstand the specific pressures of various applications but also be compatible with different media, including water, oil, and chemicals. Furthermore, the American National Standards Institute (ANSI) emphasizes the importance of adhering to applicable standards to mitigate the risks associated with hose failure. This guide aims to navigate through the complexities of choosing the right high pressure hose tailored to your unique needs, ensuring both performance and safety are prioritized.

Understanding the Different Types of High Pressure Hoses and Their Applications

When selecting high-pressure hoses for specific applications, it is crucial to understand the various types available and their intended uses. High-pressure hoses are not one-size-fits-all; they are designed to withstand different conditions, from extreme temperatures to aggressive chemicals. For instance, rubber hoses are often preferred in industrial settings because of their durability and flexibility, making them suitable for tasks such as oil and gas transfer. As observed in the growing rubber hose market, which is projected to expand significantly, industries are increasingly relying on these hoses for efficient fluid transfer.

Additionally, applications in the hydraulics and pneumatics sectors highlight the importance of specialized hoses. For example, data centers utilize hoses in liquid cooling systems to efficiently manage heat, demonstrating the versatility of high-pressure hoses beyond traditional industrial tasks. When choosing a high-pressure hose, it's essential to consider the specific environment and requirements, ensuring that the selected hose can handle the pressures and materials it will encounter.

Key Specifications to Consider When Selecting a High Pressure Hose

When selecting a high pressure hose for specific applications, it's essential to focus on key specifications that ensure performance and safety. First and foremost, consider the pressure rating, which indicates the maximum pressure the hose can handle. Choosing a hose with a suitable pressure rating for your application is crucial; using a hose rated for lower pressure can lead to catastrophic failures and safety hazards.

Additionally, take into account the hose material, as it significantly affects durability and resistance to chemicals and environmental factors. Common materials include rubber, thermoplastic, and stainless steel, each offering unique advantages depending on the intended use. Finally, hose diameter and length should match your specific requirements, as these factors influence flow rates and ease of installation. A thorough understanding of these specifications will help you choose the right high pressure hose that not only meets your operational needs but also endures the test of time and usage.

Evaluating Material Durability and Pressure Ratings for Hose Longevity

When selecting the right high-pressure hose for specific applications, understanding material durability and pressure ratings is crucial for ensuring longevity. High-pressure hoses are often subjected to intense conditions, which can lead to material degradation over time. Choosing hoses made from robust materials such as reinforced rubber or thermoplastic can enhance durability and resistance to wear and tear. It’s also important to consider the hose's pressure rating, which indicates the maximum safe operating pressure. Always select a hose with a higher pressure rating than what will be encountered in your application to avoid potential failures.

Tips: When evaluating hoses, pay attention to features like kink resistance and connection fittings. A hose that is flexible yet resistant to kinking can significantly ease handling and extend its lifespan. Additionally, look for leak-proof fittings to ensure a steady and reliable flow of fluid, which is essential in both gardening and industrial applications. By taking these factors into account, you can make a more informed decision that will prevent frustration and increase efficiency in your tasks.

Assessing Temperature Resistance and Flexibility Needs in High Pressure Hoses

When selecting a high-pressure hose for your specific application, two critical factors to consider are temperature resistance and flexibility. High-pressure hoses are often subjected to extreme conditions, and understanding the temperature limits of the materials used in the hose is essential. Different applications may require hoses that can withstand varying temperature ranges, from extremely cold to high-heat environments. Using a hose that is not rated for the specific temperature range can lead to premature wear or even catastrophic failure, ultimately impacting equipment performance and safety.

Flexibility is another crucial factor in hose selection. A hose that is too rigid can complicate the installation process and hinder maneuverability, particularly in tight spaces where flexibility is essential for proper routing and operation. Conversely, a hose that is overly flexible may not withstand the pressures involved in high-pressure applications. Assessing the flexibility needs based on your operational environment will help ensure optimal performance. Look for hoses designed to maintain integrity under pressure while also providing the necessary flexibility to accommodate dynamic movements or tight geometric configurations.

Analyzing Cost vs. Performance to Make Informed Hose Selection Decisions

When selecting a high-pressure hose, it's essential to analyze both cost and performance to ensure you make the most informed decision. While it might be tempting to choose the cheapest option available, the long-term implications can often negate any initial savings. Cheaper hoses may compromise on material quality and durability, leading to frequent replacements and downtime, which ultimately increases overall expenditure.

When evaluating potential hoses, consider their pressure rating, temperature tolerance, and compatibility with the fluids you'll be transporting. Always look for hoses that comply with industry standards, as this can significantly affect performance and safety.

**Tips:**

1. Take the time to understand the specific requirements of your application. Are there extreme temperatures or pressures involved?

2. Invest in hoses made from high-quality materials, as they typically offer better performance and longevity, making them more cost-effective in the long run.

3. Don't forget to check customer reviews or seek recommendations from industry experts to gain insights on the performance of different hose brands before making a final choice.

Cost vs. Performance of High Pressure Hoses

This chart illustrates the relationship between the cost and performance of different types of high pressure hoses, helping users to make informed choices based on their specific applications.

Related Posts

-

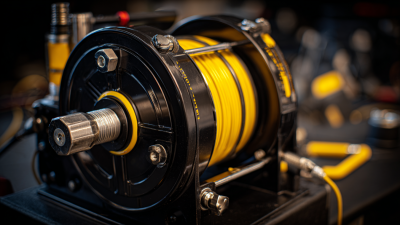

7 Essential Tips to Maximize Efficiency with Electric Hose Reels: Boost Your Productivity by 30%

-

The Definitive Ultimate Guide to Pressure Regulators: Unlocking Consistent Performance and Efficiency

-

7 Key Advantages of Using a High Pressure Hose Reel in Your Operations

-

How to Choose the Right Stainless Steel Fittings for Your Project

-

Top Strategies for Maximizing the Efficiency of Pressure Relief Valves

-

10 Amazing Benefits of Using an Air Hose Reel for Your Workshop