How to Choose the Right Industrial Hose Reel for Your Needs?

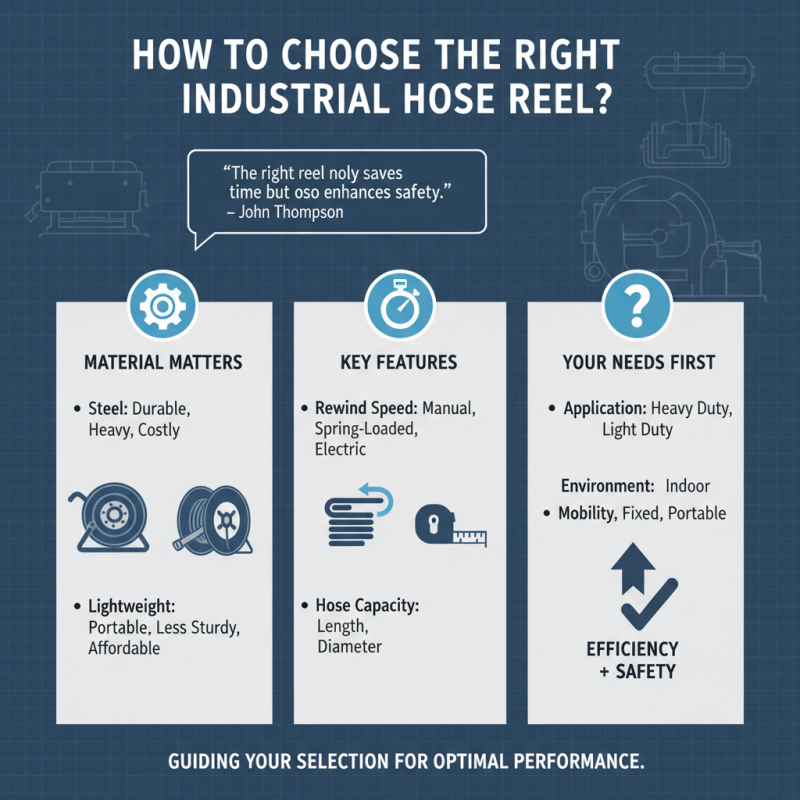

Choosing the right industrial hose reel can seem daunting. An expert in the field, John Thompson, once said, "The right reel not only saves time but also enhances safety." This insight captures the core of why proper selection is crucial.

Industrial hose reels come in various types and sizes. The material used affects durability and cost. A steel reel may last longer but can weigh more, complicating mobility. Meanwhile, lightweight options may lack the sturdiness needed for heavy-duty applications. Manufacturers often provide specifications highlighting these differences, yet the final decision heavily relies on your specific needs.

Reflecting on the many choices available, it’s easy to feel overwhelmed. Many users overlook features such as rewind speed or hose storage capacity. These details can significantly impact daily operations. Prioritizing your requirements will guide you through this process. Ultimately, a well-chosen industrial hose reel can lead to greater efficiency and improved safety.

Understanding Different Types of Industrial Hose Reels Available

When selecting an industrial hose reel, it's crucial to understand the various types available. There are manual, automatic, and mobile hose reels, each serving distinct purposes. Manual reels require physical effort to wind the hose back, making them suitable for infrequent use. Automatic reels offer convenience, as they retract the hose with just a push of a button. However, they may come with a higher price tag.

Mobile hose reels are designed for portability. These are perfect for jobs that require movement around a job site. One must consider the length and diameter of the hose they will use. For example, a larger hose may offer greater water flow but can be cumbersome to handle.

Choosing the right reel depends on your specific needs. Reflect on your work environment. Do you have space for a stationary reel? Or will a mobile one serve you better? Consider the complexities of your usage. It’s essential to find a balance between functionality and ease of use. Each type has its strengths and weaknesses that must be evaluated carefully. Sometimes, you may need to compromise on certain features to find a reel that truly fits your operational needs.

Assessing Your Specific Needs and Applications for Hose Reels

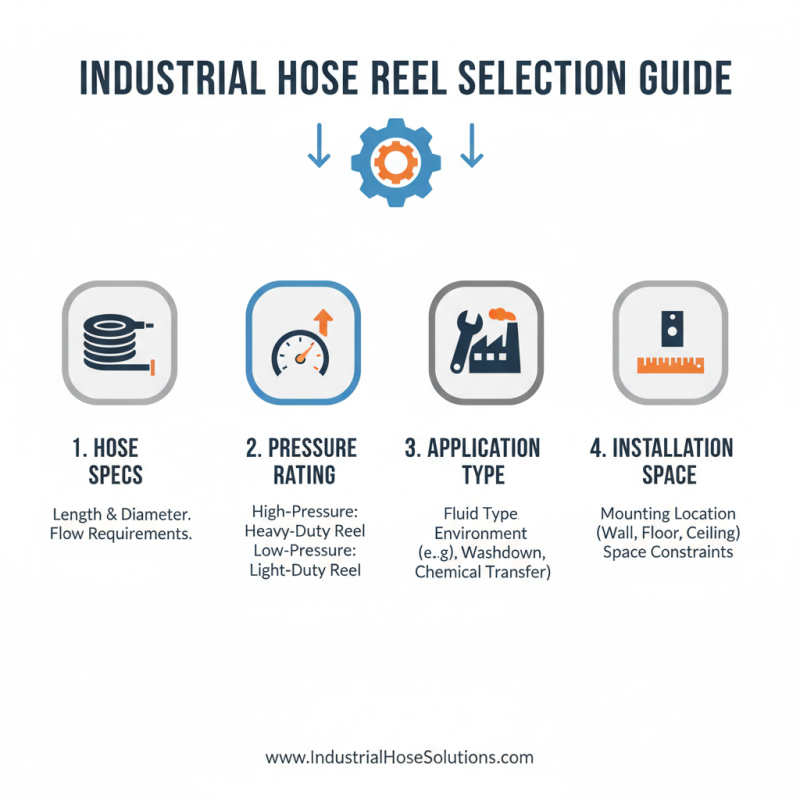

When selecting an industrial hose reel, assessing your specific needs is crucial. Different applications require different features. Consider factors like hose length and diameter. If your work involves high-pressure operations, choose a heavy-duty reel. A lightweight reel suits less demanding tasks. Identify where you will install the reel. Space constraints may affect your choice significantly.

Think about the types of fluids you will use. Some reels are better for water, while others handle chemicals well. If you deal with potential spills, a hose reel with a protective cover is wise. Ease of access is important. You don't want to struggle winding and unwinding hoses. Evaluate the reel's mobility, especially if it will move between sites.

Pay attention to material quality. A cheap reel might wear out quickly. Reflect on your budget, but don’t compromise on safety. Moreover, consider maintenance requirements. Some reels demand regular upkeep, while others are more user-friendly. Your choice should promote efficiency and safety, keeping your workspace orderly.

Key Factors to Consider When Choosing a Hose Reel

When selecting an industrial hose reel, various factors come into play. The type of hose you intend to use is critical. For instance, a study by the American National Standards Institute (ANSI) indicates that over 70% of hose failures are due to improper reel selection. Knowing whether you require a high-pressure reel or a standard one can save time and money.

Material matters too. Reels made from heavy-duty steel offer durability, especially in harsh environments. On the other hand, lightweight options made of aluminum might present easier portability. The choice relies heavily on your working conditions. For example, in an industry report from the Hose Manufacturers Association, it’s shown that approximately 60% of facilities experience wear and tear due to environmental factors.

Consider the reel’s retraction system. Automatic reels save labor but can have occasional mechanical issues. Some users have reported dissatisfaction with the consistency of the automatic systems. Manual reels, while requiring more effort, often show higher reliability. Manufacturers frequently emphasize durability, but real-world data suggests that perceived benefits may not align with actual performance under continuous use.

Evaluating Material and Durability of Hose Reels

When selecting an industrial hose reel, evaluating material and durability is crucial. Many reels use stainless steel or aluminum. These materials resist corrosion and perform well under extreme conditions. According to the Industrial Hose and Fittings Association, reels made from high-quality materials can last up to seven years longer than their cheaper counterparts.

Durability is not just about the material. It’s also about how the reel is constructed. Reinforced hoses endure more pressure. They withstand abrasion better too. A study by the American Society for Testing and Materials highlighted that using high-grade rubber can increase lifespan by 30%. Consider these factors while reviewing specs. More expensive options can save money over time. However, many users often overlook these details. They might focus solely on price and aesthetics instead.

Choosing a hose reel isn't just about immediate needs. It's about what will work best in the long run. Heavy-duty environments pose challenges. A flimsy reel might buckle under pressure. This leads to costly replacements. Reflect on your operational demands before making a decision. Performance should always take precedence over appearance.

How to Choose the Right Industrial Hose Reel for Your Needs? - Evaluating Material and Durability of Hose Reels

| Hose Reel Type | Material | Durability Rating | Max Hose Length | Weight Capacity | Price Range |

|---|---|---|---|---|---|

| Spring Driven | Steel | 5/5 | 100 ft | 300 lbs | $150 - $300 |

| Manual | Aluminum | 4/5 | 75 ft | 200 lbs | $100 - $250 |

| Motorized | Plastic Composite | 4.5/5 | 150 ft | 250 lbs | $250 - $500 |

| Reel with Stand | Stainless Steel | 5/5 | 100 ft | 400 lbs | $200 - $350 |

Maintenance and Care Tips for Your Industrial Hose Reel

Proper maintenance of industrial hose reels is crucial for longevity. A study by the Industrial Hose Association states that regular inspections can prevent 70% of potential failures. Visual checks ensure that hoses are free from wear and tear. Look for cracks or fraying. A well-maintained hose can last twice as long as one that is not cared for properly.

Cleaning is another essential aspect. Dirty hose reels can lead to operational inefficiencies. Dust and debris may cause the reel to malfunction. It’s advisable to clean both the hose and the reel weekly. In a busy industrial setting, this task is often overlooked. Yet, dedicating just a few minutes can save significant costs down the line.

Lubrication is key too. A light application of oil can keep the reel functioning smoothly. However, too much lubrication can attract dirt. This creates a cycle of grime and wear. Users could be tempted to ignore maintenance tasks, thinking they're unnecessary. But neglecting these practices can lead to costly repairs or replacements. Regular care can enhance reliability and extend the lifespan of hose reels significantly.

Related Posts

-

How to Choose the Right Industrial Hose Reel for Your Needs

-

7 Proven Tips for Finding the Best High Pressure Hose for Your Needs

-

How to Choose the Right Pressure Hose for Your Needs?

-

What is a pressure relief valve and how does it work?

-

Unveiling Soft Wash Pump Innovations at the 138th China Import and Export Fair 2025

-

Exploring Innovative Alternatives to Traditional Pressure Gauges in Industrial Applications