How to Choose the Right Pressure Hose for Your Needs?

Choosing the right pressure hose is crucial for any project. Tom Reynolds, a pressure hose industry expert, states, “A good hose can make all the difference.” Understanding your specific needs ensures efficiency and safety.

Pressure hoses come in various sizes and materials. These differences can impact durability and performance. For instance, a rubber pressure hose may be flexible but not as durable as a PVC hose. Evaluating the environment is essential. Will it be exposed to chemicals or extreme temperatures? Each factor matters.

It’s easy to overlook the details when selecting a pressure hose. Many forget to check the pressure ratings. You wouldn't want a hose that fails under pressure. Researching options helps avoid costly mistakes. Balancing quality with budget is challenging. Yet, making an informed decision will lead to better outcomes.

Understanding the Different Types of Pressure Hoses and Their Uses

Choosing the right pressure hose can be tricky. There are different types designed for various applications. Knowing these differences is crucial.

One common type is the rubber pressure hose. It's durable and often used in industrial settings. This type can withstand high temperatures and pressures. However, it may not be the best for every situation. For instance, it's heavy and can be cumbersome to handle. If you need flexibility, consider a PVC hose. It's lighter and easier to maneuver, but it may not endure extreme conditions.

Tips: Always check the pressure rating. A hose rated too low can burst. Also, think about the environment. Will the hose be exposed to chemicals? This can affect its durability. Choosing a hose is more nuanced than it seems. Pay attention to the details to avoid mistakes later. Choose wisely to save time and money.

How to Choose the Right Pressure Hose for Your Needs?

| Hose Type | Material | Pressure Rating (PSI) | Temperature Range (°F) | Common Uses |

|---|---|---|---|---|

| Standard Pressure Hose | PVC or Rubber | 3000 PSI | -40°F to 140°F | General Cleaning, Car Washing |

| High-Pressure Hose | Steel Reinforced Rubber | 5000 PSI | -30°F to 180°F | Industrial Cleaning, Heavy Machinery |

| Hot Water Pressure Hose | Thermoplastic or Rubber | 3000 PSI | -20°F to 250°F | Steam Cleaning, Sanitizing |

| Chemical Resistant Hose | Polyurethane | 3000 PSI | -40°F to 150°F | Chemical Cleaning, Industrial Applications |

Evaluating Pressure Ratings: PSI and Their Importance in Hose Selection

When choosing a pressure hose, understanding PSI is vital. PSI, or pounds per square inch, indicates how much pressure a hose can handle safely. A hose with a low PSI rating may burst under high pressure. For example, a 1500 PSI hose is suitable for light tasks, while a 4000 PSI hose is better for commercial use. Knowing your project's demands helps prevent potential hazards.

Consider the materials of the hose. Rubber hoses are flexible and often durable but can wear out quickly. PVC hoses resist chemicals but may not endure extreme temperatures. Each material has its pros and cons. Assess your environment. If a hose is rated for outdoor use but is exposed to heavy sunlight, it might degrade faster.

Testing the chosen hose in real scenarios can reveal weaknesses. A hose that performs well under testing might fail in rugged applications. Regular inspections are necessary, too. Look for wear and tear, especially at attachment points. Sometimes, what seems sufficient in theory doesn't perform in practice. Being aware of these factors can make the difference between efficiency and accidents.

Material Considerations: Rubber, PVC, and Reinforced Hoses Compared

When choosing the right pressure hose, material is a critical factor. Rubber hoses are known for their durability and flexibility. They can handle high pressures and extreme temperatures. Industry reports indicate that rubber hoses can withstand temperatures ranging from -40°F to 200°F. This makes them suitable for both industrial and home applications.

PVC hoses are lighter and more affordable. They resist abrasion well, but their temperature tolerance is lower than rubber. PVC hoses typically perform best in temperatures up to 150°F. They are great for lighter tasks, such as gardening or light construction. However, for heavy-duty use, they may not be the best choice.

**Tip:** Always consider your specific needs before making a choice. For high-pressure washing, rubber hoses are often recommended. Reinforced hoses combine elements of both materials for added strength. They are useful for dynamic applications where flexibility is required.

Choosing the right hose means evaluating how often and where it will be used. Not every rubber or PVC hose performs well under all conditions. Testing pressure limits and temperature ratings is essential. The wrong choice can lead to issues, so reflect carefully on your requirements.

Material Comparison of Pressure Hoses

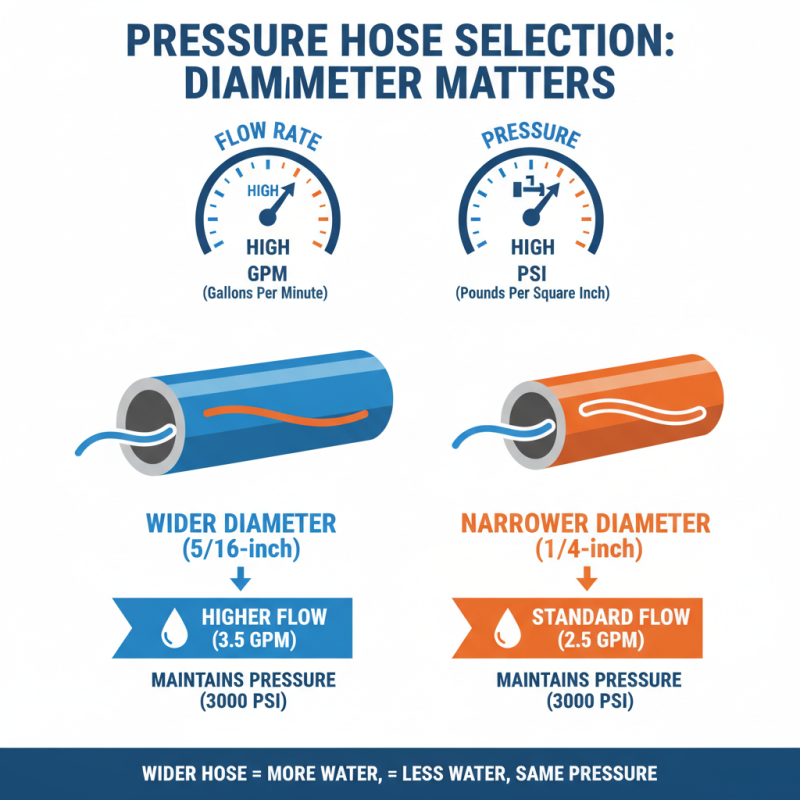

Choosing the Right Diameter: How Hose Size Affects Flow Rate and Pressure

When choosing a pressure hose, the diameter is a critical factor. It directly influences both flow rate and pressure. A wider diameter allows for higher flow rates, while a narrower hose can maintain pressure but may restrict flow. For example, a typical 1/4-inch hose can handle around 2.5 gallons per minute (GPM) at 3,000 PSI, whereas a 5/16-inch hose may increase the flow to 3.5 GPM under the same conditions. Understanding this can help you select a hose that meets your specific needs.

Tip: Always match the hose diameter with your equipment specifications. Mismatched sizes can lead to inefficiencies. For tasks requiring high pressure and flow, consider a larger hose to maximize performance. However, a larger diameter may be more cumbersome to handle.

It's also essential to note that installing the wrong diameter hose can cause pressure drops. This means less effective cleaning or operation. A poorly fitted hose can diminish the equipment's lifespan. Regularly evaluate your hose's condition and size to ensure optimal performance. Don’t overlook how subtle changes affect your work. Adjusting hose diameter might seem trivial but can yield significant results.

Industry Standards and Regulations Governing Pressure Hose Selection

When selecting a pressure hose, understanding industry standards is crucial. Various sectors have specific requirements for hose materials and performance. These standards ensure safety and efficiency. For instance, construction sites may require hoses that can withstand high temperatures and pressures. Regulatory bodies set guidelines for these applications, emphasizing the importance of compatibility with fluids.

It’s essential to evaluate the working environment. If a hose will be in contact with chemicals, it must meet certain resistance standards. Additionally, sizing is a critical factor—using the wrong diameter can lead to pressure loss. Manufacturers often provide information on their products, but interpretation can be challenging. Testing hoses under real conditions can reveal performance discrepancies. It's advisable to seek guidance, as mistakes can be costly. Understanding these nuances helps avoid issues later on. Practical knowledge about materials will enhance the selection process.

Related Posts

-

Top Tips for Choosing the Right Pressure Hose for Your Cleaning Projects

-

7 Proven Tips for Finding the Best High Pressure Hose for Your Needs

-

How to Choose the Right High Pressure Hose for Your Specific Applications

-

Why Choose Stainless Steel Ball Valves for Your Plumbing Needs

-

Unlocking the Power of Pressure Washer Pumps for Optimal Cleaning Efficiency and Performance Insights

-

Troubleshooting Common Issues with Hose Reels: Solutions You Need to Know