The Essential Guide to Understanding How Pressure Relief Valves Work

Understanding the intricacies of pressure relief valves is crucial for anyone involved in industrial operations, engineering, or maintenance. These vital components play a significant role in safeguarding systems from excessive pressure buildup, which could lead to catastrophic failures or operational inefficiencies. In this essential guide, we will delve into the mechanics of pressure relief valves, exploring their types, applications, and the critical functions they serve in various settings. With a comprehensive overview that includes practical tips and best practices, readers will not only grasp the fundamental principles behind these devices but also learn how to effectively implement and maintain them in their systems. Whether you are a seasoned professional or new to the field, this guide aims to equip you with the knowledge needed to ensure optimal performance and safety in your operations involving pressure relief valves.

Types of Pressure Relief Valves and Their Applications

Pressure relief valves (PRVs) are critical components in various industries, ensuring safety and reliability in pressurized systems. There are several types of pressure relief valves, each designed for specific applications. The most common varieties include spring-loaded, pilot-operated, and rupture disk valves. According to a recent report by MarketsandMarkets, the global pressure relief valve market is projected to grow from USD 4.27 billion in 2021 to USD 5.83 billion by 2026, highlighting the increasing importance of these devices in maintaining operational safety.

Spring-loaded valves are widely used in applications with low to moderate pressure and are well-suited for industries such as oil and gas, chemical manufacturing, and water treatment. They provide fast response times and are often more cost-effective. Conversely, pilot-operated valves are employed in high-pressure applications, such as power generation and heavy manufacturing, where they can maintain tight pressure control and reduce fluid loss, offering significant operational efficiency. According to a report from Research and Markets, pilot-operated PRVs can improve system performance by up to 15%, making them a preferred choice in environments where precision is paramount.

Understanding the Mechanism of Pressure Relief Valves

Pressure relief valves (PRVs) are critical components designed to maintain the safety and integrity of pressurized systems. These valves operate on a straightforward mechanism: they allow excess pressure to escape when it exceeds a predetermined level. Typically, this involves a spring-loaded mechanism that counteracts the system pressure. When the pressure in the system rises above the set point, the force on the valve exceeds the spring tension, causing the valve to open and release gas or liquid, thereby reducing the pressure within the system.

Tips: When selecting a pressure relief valve, ensure it is suitable for the specific application, considering factors like pressure settings, temperature ranges, and the type of fluid involved. Regular maintenance is also essential to ensure proper functionality—check for signs of wear and tear and test the valve periodically to verify its operational efficiency.

Another key aspect of PRV functionality is its sizing. An incorrectly sized valve can lead to either inadequate protection or excessive leakage. Proper sizing considers the flow rate, the characteristics of the fluid, and the potential pressure surge. This attention to detail ensures that the valve effectively prevents over-pressurization while minimizing operational losses.

Tips: Use flow calculations and pressure profiles to guide your choice of valve size, and consult with manufacturers for personalized recommendations based on your system’s specifications.

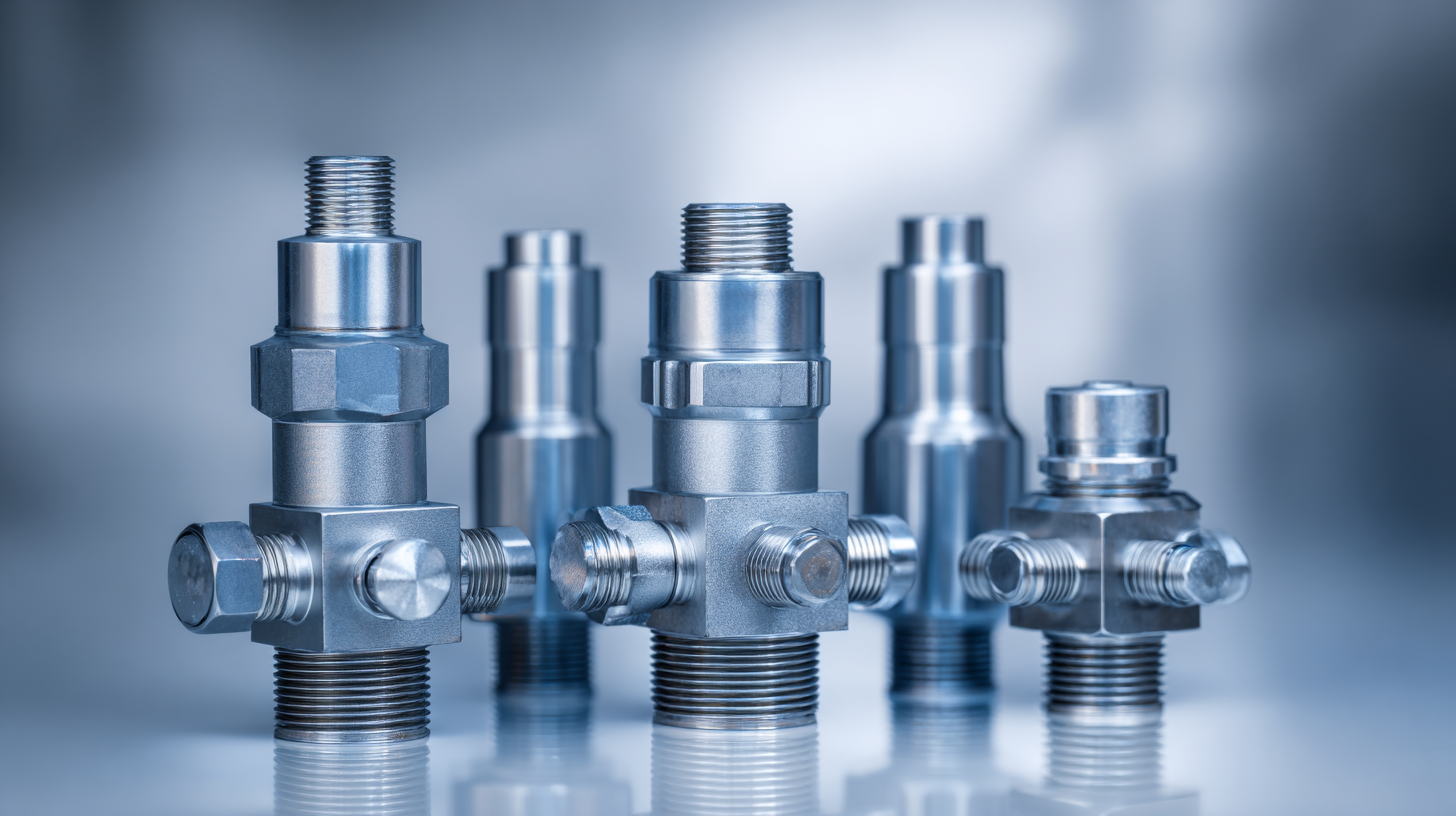

Key Components and Materials Used in Pressure Relief Valves

Pressure relief valves (PRVs) are critical components in various systems, designed to prevent excessive pressure buildup that could lead to catastrophic failures. Understanding the key components and materials used in these valves is essential for ensuring their effective operation and longevity. The primary components of a pressure relief valve include the valve body, disc or diaphragm, spring, and inlet and outlet connections. The valve body houses the internal components and is designed to withstand the pressures of the system, while the disc or diaphragm acts as the sealing element that opens to relieve pressure. The spring provides the necessary force to keep the valve closed until the preset pressure is reached.

Pressure relief valves (PRVs) are critical components in various systems, designed to prevent excessive pressure buildup that could lead to catastrophic failures. Understanding the key components and materials used in these valves is essential for ensuring their effective operation and longevity. The primary components of a pressure relief valve include the valve body, disc or diaphragm, spring, and inlet and outlet connections. The valve body houses the internal components and is designed to withstand the pressures of the system, while the disc or diaphragm acts as the sealing element that opens to relieve pressure. The spring provides the necessary force to keep the valve closed until the preset pressure is reached.

When it comes to materials, PRVs are typically made from metals like stainless steel, brass, or carbon steel, which offer strength and corrosion resistance. The choice of material often depends on the application and the type of media being handled. For example, in corrosive environments, materials like Hastelloy or other specialized alloys may be used to ensure durability. Additionally, elastomers or polymers may be used for sealing elements to provide flexibility and prevent leaks. Understanding these components and materials helps in selecting the right pressure relief valve for specific applications, ensuring safety and reliability in pressure management systems.

Safety Standards and Regulations Governing Pressure Relief Valves

Pressure relief valves (PRVs) play a critical role in maintaining the safety and integrity of pressurized systems across various industries. Adherence to safety standards and regulations is essential to ensure that these valves function properly and protect against potential hazards. Organizations such as the American Society of Mechanical Engineers (ASME) and the National Board of Boiler and Pressure Vessel Inspectors outline rigorous guidelines for the installation and maintenance of PRVs. For instance, ASME's Section VIII delineates parameters for non-code pressure vessels, emphasizing the necessity for PRVs to be capable of discharging at least 100% of the maximum expected flow rate to prevent catastrophic failure.

In addition to ASME, the Occupational Safety and Health Administration (OSHA) establishes regulations governing pressure relief systems in workplace settings. According to OSHA’s standards, it is mandatory for industries to conduct regular inspections and testing of PRVs to confirm their operational reliability. A study by the American Petroleum Institute (API) highlights that failure to comply with these regulations can lead to serious incidents; approximately 75% of industrial accidents involving pressurized equipment relate to malfunctioning safety valves. Therefore, continuous training and adherence to established safety standards are vital for ensuring the safe operation of pressure relief valves in any industrial application.

The Essential Guide to Understanding How Pressure Relief Valves Work - Safety Standards and Regulations Governing Pressure Relief Valves

| Parameter | Description | Standard | Regulation Body |

|---|---|---|---|

| Set Pressure | The pressure at which the pressure relief valve is designed to operate. | ASME BPVC | American Society of Mechanical Engineers |

| Overpressure | The allowable pressure above the set pressure before the valve begins to relieve. | API 520 | American Petroleum Institute |

| Flow Rate | The volume of fluid that can be discharged through the valve. | ISO 4126 | International Organization for Standardization |

| Testing Requirements | Specifications on how pressure relief valves should be tested for safety and reliability. | NFPA 58 | National Fire Protection Association |

| Installation Guidelines | Standards that dictate how and where pressure relief valves should be installed for optimal performance. | ASME B31.3 | American Society of Mechanical Engineers |

Common Maintenance Practices for Pressure Relief Valves

Regular maintenance of pressure relief valves is crucial to ensure their proper functioning and longevity. One essential practice is routine inspection, which involves checking for signs of wear, corrosion, or leaks. During inspections, technicians should verify that the valve opens at its designated pressure and resets correctly after activation. This can be done through testing under controlled conditions, ensuring that the valve responds appropriately to the pressure changes it is designed to manage.

Another important maintenance practice is cleaning the valve components. Accumulation of dirt and debris can interfere with the valve's operation, leading to potential failures. A thorough cleaning procedure can improve reliability and extend the life of the valve. It’s also advisable to lubricate moving parts if applicable, as this reduces friction and wear, allowing the valve to function smoothly. By incorporating these common maintenance practices into a regular schedule, industries can prevent unexpected failures and enhance the safety of their systems.

Related Posts

-

Top Strategies for Maximizing the Efficiency of Pressure Relief Valves

-

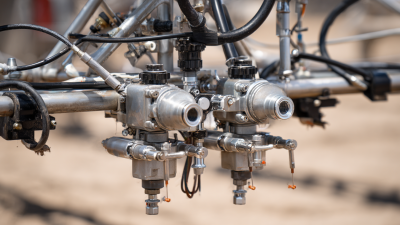

Essential Checklist for Choosing the Right Sprayer Parts to Maximize Efficiency and Performance

-

How to Choose the Right Electric Hose Reel for Your Needs

-

Exploring Innovative Sprayer Parts at the 138th Canton Fair 2025 Insights and Industry Trends

-

The Ultimate Guide to Choosing a Commercial Hose Reel for Optimal Efficiency and Durability

-

How to Choose the Right Sprayer Parts for Optimal Performance