Essential Tips for Choosing the Right Pressure Gauges?

Choosing the right pressure gauges may seem straightforward, but it requires careful consideration. Industry expert Dr. Alice Green states, "Selecting accurate pressure gauges can significantly impact operational efficiency." Understanding the types of pressure gauges available is a crucial first step.

Different applications demand different specifications. For example, hydraulic systems often require specific gauge features. It's essential to assess compatibility with the fluids and pressures involved. A mismatch may lead to inaccurate readings or even equipment failure.

However, even seasoned professionals sometimes overlook the importance of calibration and maintenance. Regular checks can ensure long-term accuracy. Making informed choices about pressure gauges can enhance performance, but it also requires ongoing attention and reflection.

Understanding the Importance of Pressure Gauges in Various Applications

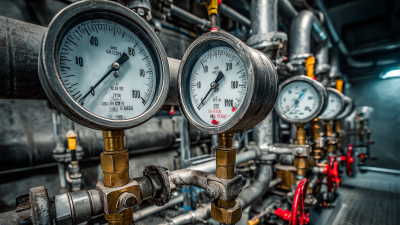

Pressure gauges play a vital role in various applications, ranging from industrial settings to HVAC systems. These instruments measure the pressure of gases or liquids, ensuring safe operations. Accurate readings help prevent machinery failures and leaks, which can lead to costly repairs or safety hazards. Many professionals rely on these gauges for their daily tasks. A simple mistake in choosing the wrong gauge can have serious consequences.

Different environments require specific types of pressure gauges. For instance, a chemical plant may need corrosion-resistant models, while a water treatment facility may focus on durability. Choosing the right material is essential. Sometimes, users overlook calibration and maintenance. Ignoring these factors can compromise the efficacy of the gauge. Also, consider the pressure range and connection size. A mismatch can disrupt the entire system.

It's important to consult with industry experts to make informed decisions. But, remember that no one knows everything. Asking questions can lead to better outcomes. Don't hesitate to seek advice from colleagues with more experience. Reflect on previous choices, analyze what worked or failed, and adjust your approach as needed.

Key Factors to Consider When Selecting Pressure Gauges

When selecting pressure gauges, several key factors warrant consideration. Accuracy is crucial. Inaccurate gauges can lead to costly errors. A gauge with a range of ±1% is often recommended for most applications. Consider the environment too. Temperatures and humidity can affect gauge performance. In hostile environments, select gauges with protective features.

Materials play an essential role. Stainless steel is common due to its durability and corrosion resistance. However, some applications may require brass or plastic materials. Each material has its trade-offs that should be evaluated based on your needs.

Tips: Always assess the calibration requirements. Regular calibration ensures accurate readings. Maintain a checklist for compatibility with existing systems. Finally, don’t ignore user-friendliness. A gauge should be easy to read. Complex designs may hinder quick assessments, risking safety.

Essential Tips for Choosing the Right Pressure Gauges

| Factor | Consideration | Example Values |

|---|---|---|

| Pressure Range | Select a gauge that fits within the expected pressure levels | 0-150 PSI, 0-300 Bar |

| Accuracy | Ensure the gauge meets required precision for the application | ±1%, ±0.5% |

| Media Compatibility | Check materials for compatibility with the fluid or gas | Water, Oil, Gas, Chemicals |

| Temperature Range | Gauge should withstand operating temperature | -20°C to 80°C, 0°F to 250°F |

| Connection Type | Match the connection format with your piping system | NPT, BSP, Flange |

| Dial Size | Choose an appropriate size for visibility and readability | 2.5", 3.5", 4" |

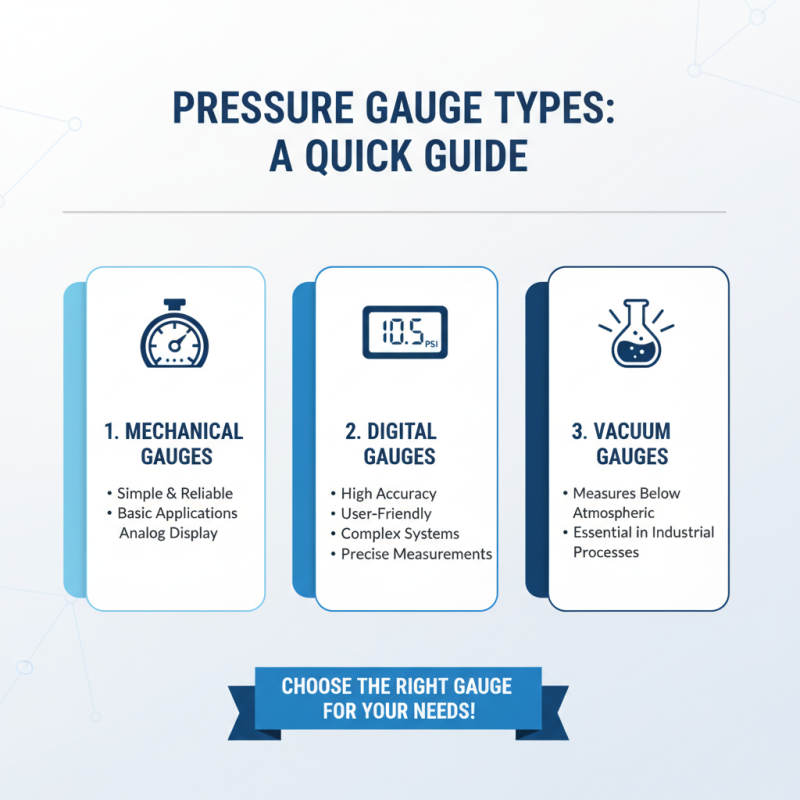

Different Types of Pressure Gauges and Their Suitability

When selecting the right pressure gauge, understanding the different types available is crucial. There are three main types: mechanical, digital, and vacuum gauges. Mechanical gauges are simple and reliable. They are suited for basic applications. Digital gauges offer higher accuracy and are user-friendly. They can be used in complex systems for precise measurements. Vacuum gauges measure pressure below atmospheric levels. They are essential in many industrial processes.

Tip: Always consider the measurement range of the gauge. Choose one that matches your application. Also, think about environmental factors. Some gauges perform poorly in extreme temperatures or humidity.

Another important aspect is calibration. Regular calibration ensures accuracy. A gauge that hasn’t been calibrated may give false readings. This can lead to critical errors in operations.

Lastly, be mindful of the installation. Improperly installed gauges can lead to damage or incorrect readings. A poorly placed gauge might not respond as needed. Consider these factors carefully to make the best choice.

Material and Design Considerations for Durability and Accuracy

When selecting pressure gauges, durability and accuracy are crucial. The materials used greatly affect these two factors. Stainless steel is a popular choice due to its resistance to corrosion. It excels in various environments, making it suitable for industrial applications. Look for gauges with high-quality seals to enhance longevity.

Another important consideration is the design. The gauge should have a clear and easy-to-read dial. Some designs may be prone to damage over time. Transparent windows might scratch easily, obscuring readability. Choosing a gauge with a protective cover can mitigate this issue.

Tips: Always check the specifications. Ensure the gauge can handle the pressure range you need. Consider the medium being measured; some materials are unsuitable for certain fluids or gases. It's a good idea to collect user feedback on gauges. Experiences shared can highlight both strengths and weaknesses you may not have considered.

Calibrating and Maintaining Pressure Gauges for Optimal Performance

Calibrating pressure gauges is crucial for accuracy. Many professionals overlook calibration, leading to inefficient processes. According to industry reports, up to 30% of pressure gauges may become inaccurate without regular checks. Calibration should be done regularly, ideally every six months.

Maintaining pressure gauges ensures long-term performance. Factors such as temperature and vibration can impact readings. Cleaning and inspecting connections regularly can prevent faults. An unnoticed leak or blockage can compromise accuracy. Even minor errors lead to significant operational issues.

It's also essential to choose the right calibration method. Some gauges may require electronic calibration, while others may work with traditional methods. Selecting the wrong approach may lead to erroneous readings. Ensure your calibration practices align with industry standards for optimal results. Regular maintenance cannot be ignored; neglect can lead to costly downtime.

Essential Tips for Choosing the Right Pressure Gauges

This chart illustrates the performance metrics of different types of pressure gauges based on their calibration frequency and maintenance. Regular calibration and maintenance are essential to ensure optimal accuracy and longevity of pressure gauges.

Related Posts

-

Ultimate Pressure Gauges Procurement Checklist for Global Buyers

-

Exploring Innovative Alternatives to Traditional Pressure Gauges in Industrial Applications

-

How to Choose the Right Pressure Gauge for Your Industrial Applications

-

How to Choose the Best Pressure Gauges for Your Needs in 2025

-

How to Choose the Right Pressure Gauges for Your Industrial Needs

-

What is a High Pressure Hose? Understanding Applications and Benefits