As the demand for lightweight and durable materials continues to rise across various industries, the role of Aluminum Die Casting has become increasingly pivotal. According to a recent report by MarketsandMarkets, the global aluminum die casting market is expected to reach approximately $6.34 billion by 2025, growing at a CAGR of 9.4% from 2020. This remarkable growth is being driven by advancements in manufacturing technologies, which enable enhanced precision, strength, and efficiency in die casting processes. Buyers around the world are now looking for innovative solutions that not only meet their quality and performance standards but also contribute to sustainability efforts. As we delve into the future of advanced aluminum die casting solutions, it is essential to explore how these innovations can bridge the gap between industry demands and the need for sustainable practices, catering to a diverse array of applications from automotive to aerospace and beyond.

As the aluminum die casting industry evolves, several challenges are anticipated in 2024 that could impact global buyers. According to a recent report by Allied Market Research, the global die casting market is expected to reach $30 billion by 2026, with aluminum die casting experiencing robust growth due to its lightweight properties and durability. However, manufacturers must navigate complexities such as rising raw material costs and labor shortages, which could hinder production efficiencies. The price of aluminum has seen fluctuations, projected to rise by approximately 5% over the next year, influenced by geopolitical tensions and supply chain disruptions.

Additionally, the environmental impact of aluminum production remains a pressing concern. The International Aluminum Institute reports that the aluminum industry accounts for about 1.1 billion tons of CO2 emissions annually, prompting buyers to prioritize manufacturers that leverage sustainable practices. Adopting advanced technologies such as pressure die casting and utilizing recycled aluminum could mitigate these challenges. Innovations in automation and smart manufacturing are also critical as companies strive to enhance productivity while adhering to stringent environmental regulations. Addressing these issues is essential for the continued growth and competitiveness of the advanced aluminum die casting market.

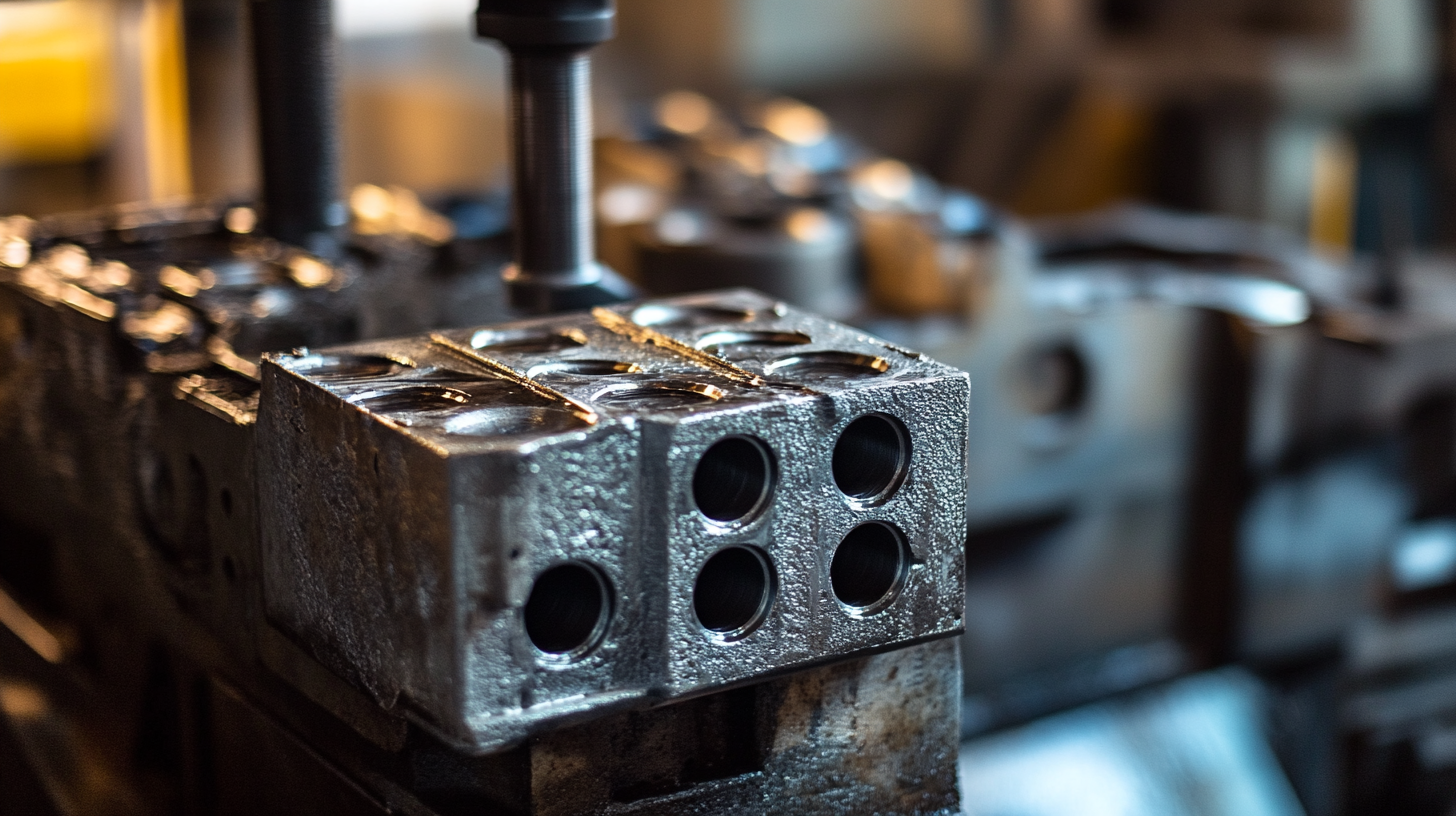

In the realm of advanced aluminum die casting, innovation plays a crucial role in addressing prevalent challenges faced by manufacturers worldwide. A recent report by Grand View Research indicates that the global die casting market is projected to reach $79.64 billion by 2027, reflecting an increasing demand for high-quality aluminum components across various industries. One of the most common issues in die casting is the occurrence of defects such as porosity and dimensional inaccuracies, which can significantly affect the end product's performance and reliability. To combat these issues, companies are embracing cutting-edge technologies like real-time monitoring systems and advanced simulation software, which enhance process control and reduce scrap rates.

In the realm of advanced aluminum die casting, innovation plays a crucial role in addressing prevalent challenges faced by manufacturers worldwide. A recent report by Grand View Research indicates that the global die casting market is projected to reach $79.64 billion by 2027, reflecting an increasing demand for high-quality aluminum components across various industries. One of the most common issues in die casting is the occurrence of defects such as porosity and dimensional inaccuracies, which can significantly affect the end product's performance and reliability. To combat these issues, companies are embracing cutting-edge technologies like real-time monitoring systems and advanced simulation software, which enhance process control and reduce scrap rates.

Moreover, sustainability has become a focal point in die casting solutions. The Aluminum Association has reported that aluminum recycling saves 90% of the energy required to produce new aluminum, thereby decreasing the environmental impact. This shift towards sustainable practices is driving innovations in die casting techniques, such as the development of low-pressure die casting methods that minimize material waste and energy consumption. By leveraging such solutions, global buyers can not only improve operational efficiency but also align with environmental standards, making them an integral part of the future of the aluminum die casting industry.

The global supply chain disruptions caused by the pandemic have significantly impacted various industries, including the aluminum die casting sector. These disruptions have exposed vulnerabilities in production and logistics, leading to delays and increased costs for manufacturers and their buyers. With a considerable reliance on international suppliers for raw materials and equipment, companies are scrambling to adapt their strategies to ensure continuity and efficiency in their operations.

One of the key responses to these challenges has been the acceleration of technological innovations in aluminum die casting processes. Investing in advanced automation and AI-driven solutions allows manufacturers to streamline production, reduce waste, and enhance overall productivity. Furthermore, by diversifying supply sources and exploring local partnerships, companies can mitigate risks associated with international shipping and supply shortages. As the industry looks toward the future, these strategies not only address current disruptions but also position businesses to thrive in an increasingly competitive landscape.

As global environmental regulations become increasingly stringent, the aluminum die casting industry faces significant challenges and opportunities. According to a report by Grand View Research, the global die casting market is anticipated to reach USD 83.87 billion by 2025, driven largely by the automotive and aerospace sectors, which are now prioritizing sustainability in their manufacturing processes. Emphasizing compliance with regulations not only minimizes legal risks but also enhances corporate reputations among environmentally conscious consumers.

Tip: To align your die casting practices with environmental standards, consider investing in eco-friendly materials and adopting energy-efficient technologies. The use of recycled aluminum can reduce carbon emissions by an impressive 95% compared to primary aluminum production, showcasing the importance of sustainable sourcing in die casting.

Furthermore, shifts in regulatory frameworks, such as the European Union's Green Deal, are motivating buyers to seek partnerships with manufacturers that demonstrate a commitment to reducing their environmental footprint. Those who incorporate advanced casting techniques and sustainable practices will be better positioned to meet the evolving demands of the market while fulfilling regulatory requirements.

Tip: Engage in continuous training for your workforce to keep them informed about the latest technologies and best practices in sustainable die casting. This investment in human capital will drive innovation and compliance within your operations, ensuring long-term success in this changing landscape.

The landscape of aluminum die casting is poised for transformative changes as we move into 2025. Buyers should prepare for evolving trends that will shape their sourcing decisions. A notable shift is the decline in silicon metal prices, which have fallen consistently since early January 2025, boasting a stabilization by the end of the month. This trend could lead to more cost-effective production methods in aluminum die casting, enhancing the competitiveness of aluminum products in various markets.

Additionally, the upcoming public hearing on the Section 232 investigation into aluminum imports emphasizes the critical intersection of national security and supply chain management. As tariffs and regulations fluctuate, global buyers must remain vigilant about the potential impacts on aluminum pricing and availability. Current reports indicate that the aluminum scrap market is also experiencing notable supply and demand dynamics, influenced by economic shifts worldwide. Understanding these trends will be essential for buyers aiming to navigate future challenges and capitalize on emerging opportunities in aluminum die casting.

| Trend | Description | Impact on Buyers | Expected Developments |

|---|---|---|---|

| Sustainability Integration | Increased focus on eco-friendly materials and processes in aluminum die casting. | Buyers will prioritize suppliers with sustainable practices. | Enhanced recycling processes and reduced carbon footprint. |

| Technological Advancements | Adoption of advanced technologies like AI and automation in manufacturing. | Higher quality products with fewer defects expected by buyers. | Increased efficiency and reduced production times. |

| Customization Options | Demand for tailored solutions to meet specific client needs. | Greater flexibility in product design and functionality. | Expansion of services providing custom die casting features. |

| Cost Efficiency | Focus on reducing costs through efficient production methods. | Competitive pricing and improved profit margins for buyers. | Investment in innovative processes and materials to cut costs. |

| Global Supply Chain Optimization | Enhancements in logistics and supply chain management. | Faster delivery times and enhanced reliability. | Increased digital tools for supply chain transparency. |