The Ultimate Guide to Choosing a Commercial Hose Reel for Optimal Efficiency and Durability

When it comes to improving operational efficiency in various industries, the selection of the right equipment is crucial, and a commercial hose reel is no exception. According to a recent report by the Industrial Supply Association, organizations can enhance productivity by up to 30% by implementing quality hose management solutions. A well-chosen commercial hose reel not only streamlines workflow but also maximizes safety and durability, minimizing potential hazards associated with tangled hoses. With numerous options available in the market, understanding key features and specifications becomes essential for making an informed decision. This guide aims to equip you with the knowledge required to choose a commercial hose reel that meets your specific operational needs and withstands the rigors of everyday use.

Understanding Different Types of Commercial Hose Reels for Your Needs

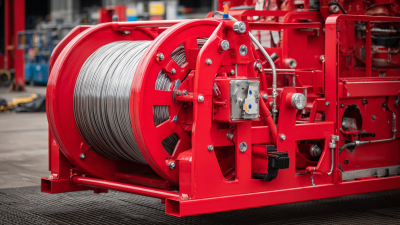

When selecting a commercial hose reel, it’s essential to understand the different types available and how they can meet your specific needs. There are various styles, including wall-mounted, portable, and stationary reels. Wall-mounted reels are ideal for saving space in smaller facilities, while portable options provide the flexibility to move hoses around as needed. Stationary reels are perfect for large operations that require a fixed setup for increased efficiency.

When selecting a commercial hose reel, it’s essential to understand the different types available and how they can meet your specific needs. There are various styles, including wall-mounted, portable, and stationary reels. Wall-mounted reels are ideal for saving space in smaller facilities, while portable options provide the flexibility to move hoses around as needed. Stationary reels are perfect for large operations that require a fixed setup for increased efficiency.

Tips: Consider the length and diameter of the hose you need. A reel that can accommodate your hose size will prevent kinks and tangles, enhancing durability. Additionally, think about the material of the reel; steel models tend to last longer in harsh environments compared to plastic ones.

Another factor to consider is the reel's winding mechanism. Manual reels are often more affordable, but automatic reels provide convenience and speed, particularly in busy commercial settings. When choosing a hose reel, weigh the importance of ease of use versus budget constraints to find the best fit for your operations.

Key Features to Consider for Maximum Efficiency in Hose Reels

When selecting a commercial hose reel, key features play a crucial role in ensuring optimal efficiency and durability. First and foremost, hose length and diameter are essential considerations; choosing a reel that accommodates the specific size and length of your hoses can prevent tangling and facilitate smooth operation. A durable, flexible hose made from high-quality materials will withstand daily wear and tear, while compatibility with various accessories can enhance versatility during use.

Another vital feature is the reel's construction and mounting options. Heavy-duty materials, such as stainless steel or reinforced plastic, contribute to resilience and longevity, making them ideal for commercial environments. Additionally, consider whether the reel is portable or wall-mounted to suit your space constraints and mobility needs. Features like automatic rewind mechanisms can significantly improve efficiency, reducing the time spent managing hoses and minimizing the risk of accidents. Ultimately, focusing on these key elements will ensure that your hose reel meets the demands of your specific application while providing reliable service for years to come.

Durability Factors: Materials and Designs that Stand the Test of Time

When selecting a commercial hose reel, durability is pivotal in ensuring long-term efficiency and cost-effectiveness. Various materials such as stainless steel, aluminum, and heavy-duty plastics play crucial roles in the reel's lifespan. According to a report by the American Society of Mechanical Engineers (ASME), stainless steel reels can offer a lifespan increase of up to 30% compared to their plastic counterparts due to their resistance to corrosion, rust, and physical damage. This durability translates directly into reduced maintenance costs over time.

Moreover, the design of the hose reel significantly influences its durability. Features such as reinforced fittings, brass connectors, and weatherproof coatings can enhance resilience. A study by the Hose and Rubber Manufacturers Association (HRMA) highlights that commercially designed hose reels with these features can withstand severe weather conditions, extending their operational life. Investing in such designs not only mitigates frequent replacements but also ensures consistent performance in various environments, making them a wise choice for any business looking to maximize efficiency and durability in their operations.

The Ultimate Guide to Choosing a Commercial Hose Reel for Optimal Efficiency and Durability

| Material | Design Type | Durability Rating (Years) | Best Use Cases |

|---|---|---|---|

| Stainless Steel | Wall-Mounted | 15 | Heavy-duty environments. |

| Aluminum | Portable | 10 | Landscaping and light industrial use. |

| Plastic | Retractable | 5 | Home and garden use. |

| Rubber | Cart Mounted | 12 | Agricultural fields and rugged terrain. |

Comparing Manual vs. Automatic Hose Reels for Optimal Convenience

When choosing between manual and automatic hose reels for commercial applications, it's essential to consider the operational efficiency and workload requirements. Manual hose reels, while typically more economical, often require more physical effort and time to operate. According to a report by the Hose Reel Manufacturers Association, manual reels can result in a 20% decrease in productivity due to the time spent in unwinding and rewinding hoses. This downtime can accumulate significantly in high-usage environments, leading to inefficiencies in work processes.

On the other hand, automatic hose reels are designed to enhance convenience and reduce labor. As noted in a study by the Industrial Supply Association, automatic reels can increase operational efficiency by up to 30%, as they allow for faster hose retrieval and storage, minimizing the risk of kinks and tangles. Furthermore, the investment in automatic systems pays off in reduced wear and tear on hoses, leading to a longer lifespan and lower replacement costs—reportedly, automatic hose reels show a 15% longer life expectancy compared to their manual counterparts. Ultimately, choosing the right type of hose reel is crucial for optimizing both convenience and overall functionality in commercial settings.

Maintenance Tips to Enhance the Longevity of Your Hose Reel

When choosing a commercial hose reel, maintenance should be at the forefront of your decision-making process. Proper care can significantly enhance the longevity of your hose reel while ensuring optimal performance. According to industry experts, regularly cleaning the hose reel after each use is crucial to removing dirt and debris that can cause wear and tear. Moreover, storing the reel in a shaded area can help prevent damage from UV rays, which can degrade the materials over time.

Additional maintenance tips include checking for kinks or twists in the hose, which can lead to leaks or functional issues. A report from the Hose Reel Manufacturers Association indicates that nearly 30% of hose failures are attributed to improper handling and storage. To further extend the lifespan of your hose reel, consider lubricating the reel mechanism every few months to ensure smooth operation. Routine checks for rust or corrosion, especially in metal reels, can also prevent costly replacements and ensure your equipment remains efficient for years to come.

Related Posts

-

5 Best Strategies for Choosing the Right Hose Reel for Your Needs

-

Troubleshooting Common Issues with Hose Reels: Solutions You Need to Know

-

7 Key Advantages of Using a High Pressure Hose Reel in Your Operations

-

Why Choosing a Heavy Duty Hose Reel Can Boost Efficiency by 30% in Industrial Settings

-

Exploring Stainless Steel Ball Valve Innovations at the 2025 China Import and Export Fair

-

Essential Checklist for Choosing the Right Sprayer Parts to Maximize Efficiency and Performance