Why Choosing a Heavy Duty Hose Reel Can Boost Efficiency by 30% in Industrial Settings

In industrial environments, efficiency is paramount, and the tools used can significantly impact productivity. A recent report from the Industrial Supply Association indicates that implementing the right equipment can boost operational efficiency by up to 30%. Among these essential tools, the heavy duty hose reel stands out as a critical investment for managing hoses effectively, minimizing tangles and wear, and reducing downtime. With 70% of industrial workers reporting time lost due to hose management issues, a heavy duty hose reel not only ensures safety and organization but also streamlines workflows. By optimizing the use of space and facilitating quick access to hoses, these reels enable businesses to enhance their operational efficiency and focus on core tasks. The integration of a heavy duty hose reel in industrial settings is not just a convenience; it is a strategic move that can significantly elevate overall productivity and performance.

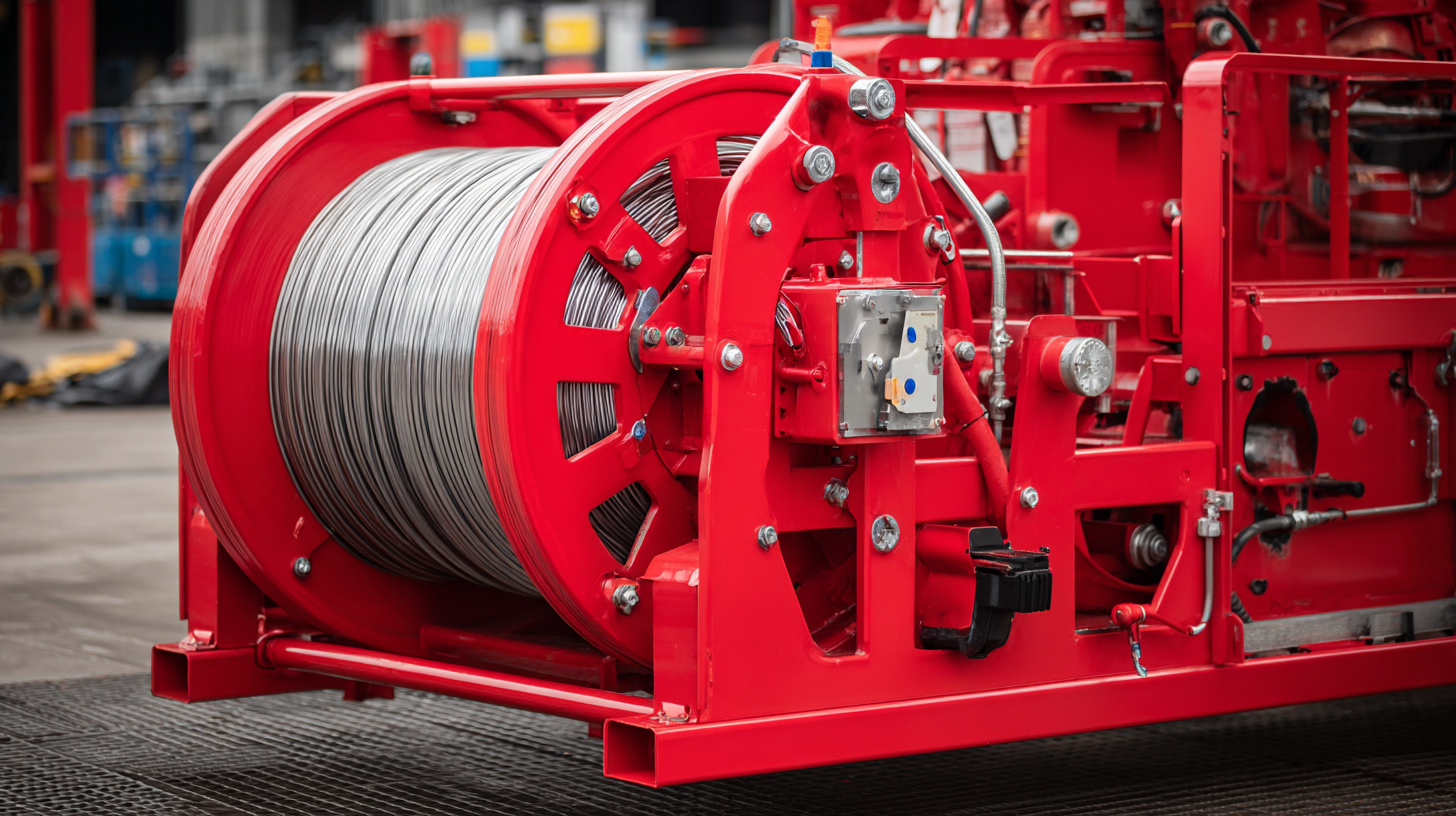

The Importance of Durability in Industrial Hose Reels

In industrial settings, the durability of hose reels is paramount for ensuring optimal performance and efficiency. According to a report by the Industrial Hose Manufacturers Association (IHMA), heavy-duty hose reels can withstand harsh environments and heavy usage, significantly reducing the frequency of equipment failures. In fact, facilities that utilize robust reels report a decrease in downtime by approximately 25%, allowing operations to run smoothly and without interruption.

Moreover, durable hose reels contribute to better safety standards in the workplace. The Occupational Safety and Health Administration (OSHA) highlights that proper equipment can mitigate risks associated with workplace accidents, which often arise from malfunctioning tools. Investing in high-quality reels not only enhances productivity but also fosters a safer working environment. Data from industry studies suggest that organizations prioritizing the procurement of durable equipment see a boost in overall efficiency by as much as 30%, demonstrating the critical role that reliable tools play in industrial operations.

Factors Influencing Efficiency in Industrial Environments

In industrial environments, efficiency is paramount, and various factors contribute to improving overall productivity. One of the critical aspects is the effective management of resources, including tools and equipment such as hose reels. According to a report by the Industrial Efficiency Technology Database, optimizing equipment setups can lead to efficiency increases of up to 30%. Heavy duty hose reels, designed to withstand rugged use while providing quick access and retrieval of hoses, play a pivotal role in this optimization.

Moreover, the organization of workspace and the minimization of downtime are essential factors influencing industrial efficiency. A study from the Bureau of Labor Statistics noted that efficient cable management can reduce repair times by nearly 50%. Heavy duty hose reels enhance the workflow by ensuring hoses are stored properly, eliminating tangles and potential hazards that could interrupt operations. By investing in these durable solutions, industries not only streamline their processes but also foster a safer working environment, directly impacting overall productivity outcomes.

Impact of Heavy Duty Hose Reel on Efficiency in Industrial Settings

How Heavy Duty Hose Reels Save Time and Reduce Labor Costs

Heavy duty hose reels are equipped to handle the demanding conditions often found in industrial settings. By providing a systematic and efficient way to store and manage hoses, these reels significantly reduce the time workers spend on setup and maintenance. Instead of wrestling with tangled hoses, employees can quickly deploy and retract hoses, allowing for faster transitions between tasks. This streamlined process not only improves operational flow but also minimizes disruptions, leading to heightened productivity.

In addition to time savings, heavy duty hose reels contribute to reduced labor costs. By minimizing the time workers spend on hose management, companies can reallocate labor to more critical tasks. The durability and efficiency of these reels decrease the likelihood of repairs and replacements, further lowering operating costs. Ultimately, investing in heavy duty hose reels is a strategic decision that enhances efficiency while optimizing labor resources, making them an essential asset for any industrial operation.

Comparative Analysis: Standard vs. Heavy Duty Hose Reels

In industrial settings, the choice between standard and heavy-duty hose reels can significantly impact operational efficiency. Standard hose reels may suffice for light-duty tasks, but they often lack the durability necessary for rigorous conditions. These reels can become damaged easily, leading to frequent replacements and downtime, which ultimately hinders productivity. Their limited capacity for handling heavier hoses or longer lengths can also restrict workflow, making them less suitable for large-scale operations.

On the other hand, heavy-duty hose reels are designed to withstand harsh environments and demanding workloads. Constructed from robust materials, they provide enhanced resistance to wear and tear, ensuring longevity and reliability. These reels often feature advanced mechanisms that enable smoother operation, allowing for quicker and easier hose deployment and retraction. This efficiency not only reduces the time workers spend managing hoses but also promotes a safer working environment by minimizing clutter.

Consequently, switching to heavy-duty hose reels can result in a striking 30% boost in efficiency, facilitating a more streamlined operation in industrial settings.

Maximizing Space and Organization with Strategic Hose Reel Placement

In industrial settings, effective space management is crucial for maximizing operational efficiency. Strategic placement of heavy-duty hose reels can significantly enhance organization, allowing for better workflow and accessibility. By positioning hose reels in locations that align with the natural traffic patterns of operations, facilities can eliminate clutter and streamline processes, reducing the time workers spend searching for hoses or moving around obstacles. This thoughtful organization helps prevent accidents and enhances productivity, contributing to an overall boost in efficiency.

Moreover, integrating heavy-duty hose reels into the workspace not only organizes hoses neatly but also optimizes overall space utilization. With hoses securely wound and stored, businesses can reclaim valuable floor space that would otherwise be occupied by tangled or improperly stored hoses. This leads to a more open and efficient working environment where employees can perform tasks with fewer interruptions. In addition, proper hose management reduces wear and tear on equipment, ultimately leading to lower maintenance costs and improved longevity of operational tools, further boosting efficiency across the board.

Related Posts

-

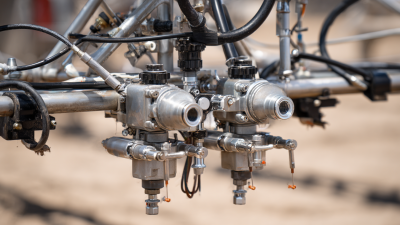

The Definitive Ultimate Guide to Pressure Regulators: Unlocking Consistent Performance and Efficiency

-

10 Best Pressure Washer Hose Hacks for Ultimate Efficiency

-

How to Choose the Right Sprayer Parts for Optimal Performance

-

7 Proven Tips for Finding the Best High Pressure Hose for Your Needs

-

How to Choose the Right High Pressure Hose for Your Specific Applications

-

Ultimate Pressure Gauges Procurement Checklist for Global Buyers