2025 How to Choose the Right Pressure Washer Fittings for Your Needs

Choosing the right pressure washer fittings is essential for ensuring optimal performance and efficiency in any cleaning task. As an expert in the field, John Smith, a renowned pressure washer technician, emphasizes, “The right fittings not only enhance the functionality of your pressure washer but also promote safety and reliability during use.” With a myriad of options available in the market, users may find themselves overwhelmed by the various types and specifications of pressure washer fittings.

Understanding the specific needs of your pressure washing projects is crucial. Whether you’re tackling heavy-duty cleaning tasks or simple home maintenance, selecting the proper fittings can make a significant difference in achieving the desired results. Misalignment or incorrect fittings can lead to pressure loss, water leaks, and even potential damage to the equipment. Thus, a solid knowledge of the types of fittings, including quick connects, couplings, and adapters, can empower users to make informed decisions tailored to their specific requirements.

In this guide, we will delve into the most important factors to consider when choosing pressure washer fittings. From compatibility with existing equipment to the material quality and pressure ratings, we aim to provide you with comprehensive insights that will enhance your pressure washing experience. By investing time in selecting the right fittings, you can unlock the full potential of your pressure washer and achieve outstanding cleaning results.

Understanding the Types of Pressure Washer Fittings Available in 2025

When selecting the ideal pressure washer fittings in 2025, it is essential to understand the various types available. Among the most common types are quick-connect fittings, which allow for easy attachment and detachment of hoses and nozzles.

These fittings come in various sizes and configurations, accommodating the diverse needs of different pressure washing tasks, from light-duty home cleaning to heavy-duty industrial use. Their design not only enhances convenience but also helps maintain consistent pressure throughout the cleaning process.

Another important category is the threaded fittings, which offer a more secure connection, making them a popular choice for prolonged use. These fittings typically require a wrench for installation, ensuring a tighter seal that minimizes the risk of leaks and pressure loss.

Additionally, specialized fittings such as extension wands and rotating nozzle connectors can enhance versatility and efficiency, allowing users to reach difficult areas or apply powerful jets of water for stubborn grime. Understanding these options will help users make informed decisions tailored to their specific pressure washing requirements.

Key Specifications to Consider When Selecting Pressure Washer Fittings

When selecting pressure washer fittings, several key specifications must be considered to ensure optimal performance and compatibility with your equipment. The first aspect is the material of the fittings. Common materials include brass, stainless steel, and plastic. Brass and stainless steel fittings are known for their durability and resistance to corrosion, making them ideal for high-pressure applications where longevity is crucial. On the other hand, plastic fittings are lighter and more affordable, suitable for lighter duties but may wear out faster under heavy use.

Another critical specification is the fitting size, which directly affects the connection between hoses and pressure washers. It's essential to match the fittings to the hose diameter and the pressure washer outlet size. The most common sizes are 1/4 inch and 3/8 inch, but it’s important to verify dimensions as they vary between different types of equipment. Additionally, consider the connection type—quick-connect fittings allow for easier interchangeability between accessories, while threaded fittings provide a more secure connection that can handle higher pressures.

Lastly, the pressure rating of the fittings should not be overlooked. Each fitting comes with a maximum pressure rating, and using a fitting that cannot handle the pressure output of your washer can lead to leaks or failures. It is advisable to choose fittings that exceed the pressure rating of your washer to ensure reliability during use. By focusing on these key specifications—material, size, connection type, and pressure rating—you can effectively choose the right pressure washer fittings tailored to your specific needs.

Evaluating Material Durability and Compatibility for Pressure Washer Fittings

When selecting the right pressure washer fittings, evaluating material durability and compatibility is crucial to ensuring optimal performance.

According to a report from the American Cleaning Institute, the durability of fittings can significantly affect the overall efficiency and lifespan of pressure washing equipment. High-quality materials resist corrosion, wear, and pressure fluctuations, which are prevalent during intensive cleaning tasks.

Fittings made from brass, stainless steel, or high-impact plastic are generally preferred due to their ability to withstand extreme conditions without degrading.

Compatibility is another key factor to consider, as improper fittings can lead to leaks, reduced pressure, and inefficient cleaning results. Industry studies indicate that up to 30% of performance issues in pressure washers stem from the use of incorrect or substandard connections.

For instance, ensuring that the fittings align properly with the hose and spray gun specifications can prevent unnecessary downtime and enhance user safety. Additionally, verifying compatibility with specific washer models can minimize the risk of malfunction and extend equipment longevity.

Choosing the right materials and ensuring compatibility not only boosts performance but also contributes to sustainable cleaning practices by reducing waste and equipment replacement.

Analyzing Flow Rate and Pressure Compatibility in Fittings Selection

When selecting pressure washer fittings, understanding flow rate and pressure compatibility is crucial. Each fitting is designed to handle specific pressure ratings and flow rates, which can greatly affect the performance of your pressure washer. If the flow rate of your fittings is too low, it can create a bottleneck, reducing the overall efficiency and effectiveness of your cleaning tasks. Conversely, using fittings that are not rated for the pressure your machine produces may lead to leaks or even damage.

Tips for choosing the right fittings include first determining the maximum pressure and flow rate of your pressure washer. This information can typically be found in the user manual or on the machine's specifications label. Once you have this data, look for fittings that meet or exceed these ratings. Additionally, consider the material of the fittings; brass and stainless steel generally offer better durability compared to plastic options.

Another key tip is to pay attention to the threading and connection type. Ensure that the fittings you choose are compatible with your hoses and accessories. Mismatched threads can lead to leaks or failures during operation, which can be both frustrating and costly. By focusing on these aspects, you can effectively select the right pressure washer fittings that align with your cleaning requirements.

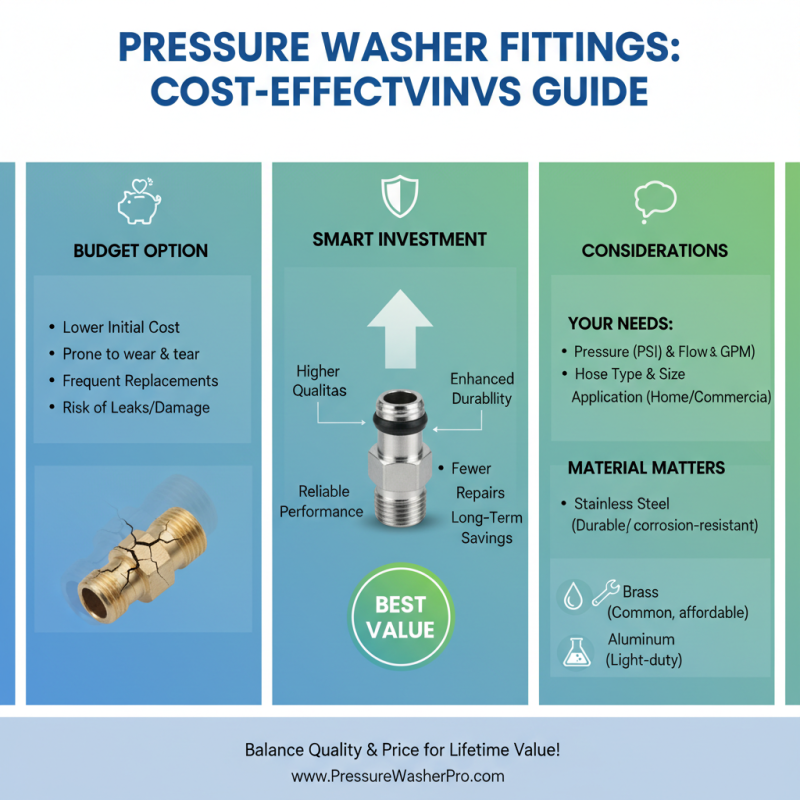

Cost-Effectiveness: Balancing Quality and Budget for Pressure Washer Fittings

When it comes to selecting pressure washer fittings, cost-effectiveness plays a crucial role in making the right choice. Many consumers face the dilemma of balancing quality and budget. While it can be tempting to opt for the cheapest fittings available, investing a bit more may yield long-term benefits. High-quality fittings often provide better durability and performance, leading to fewer replacements and repairs over time. Understanding your specific needs and use cases can further guide your decision-making process.

Tips for choosing fittings wisely include considering the material and compatibility with your pressure washer. Materials such as brass and stainless steel might come at a higher price but offer increased longevity and resistance to wear. Additionally, ensure the fittings match your washer's specifications to avoid leaks or failure under pressure. It can also be beneficial to buy in bulk if you regularly use fittings, as this may reduce the overall cost.

Another important aspect is to research available options and read customer reviews. This can help you pinpoint the best value products that won’t compromise on quality. Remember to keep an eye out for sales or promotional offers that may allow you to grab higher-quality fittings at a reduced price. Making informed decisions will ensure you achieve a balance of quality and affordability in your pressure washer fittings.

Related Posts

-

2025 Top 10 Power Washer Parts: Boost Performance & Longevity with Expert Picks

-

Top 10 Pressure Relief Valves for Optimal Safety and Performance in Industrial Applications

-

How to Choose the Right Relief Valve for Your Industrial Needs

-

How to Choose the Right Pressure Gauges for Optimal Measurement Accuracy in Industrial Applications

-

10 Amazing Benefits of Using an Air Hose Reel for Your Workshop

-

7 Essential Tips to Maximize Efficiency with Electric Hose Reels: Boost Your Productivity by 30%