What is a Pressure Regulator and How Does It Work?

In the world of fluid control systems, the pressure regulator plays a crucial role. These devices ensure stable pressure in various applications, from industrial settings to everyday appliances. According to a report by the Global Market Insights, the pressure regulator market is projected to reach $3 billion by 2026, driven by increasing demand for automation in industries.

Dr. John Collins, a recognized expert in fluid dynamics, emphasizes the importance of pressure regulators by stating, "Without effective regulation, systems become unreliable and inefficient." This highlights the necessity of these devices in maintaining operational integrity. Pressure regulators are not infallible; improper installation or maintenance can lead to failures.

Understanding how pressure regulators work is essential for maximizing their benefits. A pressure regulator manages the flow of gases or liquids, adjusting downstream pressure as needed. The complexity of these systems often goes unnoticed until issues arise, exposing the need for careful consideration and periodic reflection on their performance in various contexts.

Understanding the Definition of a Pressure Regulator

A pressure regulator is a vital device used in various systems. Its primary role is to control the pressure of gases or liquids. By maintaining a consistent pressure level, it ensures the safe and efficient operation of equipment. This is especially important in industries like gas supply and HVAC systems.

Understanding how a pressure regulator works is key. It reduces high input pressure to a lower output pressure. Typically, it consists of a spring-loaded diaphragm. This mechanism adjusts automatically as pressure fluctuates. Despite its simplicity, the regulator must be selected carefully. An improper choice can lead to inefficiency or failure.

It's also crucial to consider the limitations of pressure regulators. They may not function correctly in extreme conditions. For instance, temperature variations can impact performance. Regular maintenance is necessary to ensure reliability. This aspect is often overlooked and leads to undesirable outcomes.

What is a Pressure Regulator and How Does It Work? - Understanding the Definition of a Pressure Regulator

| Dimension | Description |

|---|---|

| Function | Regulates the pressure of fluids in a system |

| Types | Direct-acting, Pilot-operated, Electro-pneumatic |

| Applications | Gas and water distribution systems, pneumatic systems, HVAC systems |

| Common Materials | Brass, Stainless Steel, Plastic |

| Pressure Range | Typically from 0.5 psi to 100 psi, depending on the regulator |

| Maintenance | Regular inspection for leaks and wear; replacement of seals and diaphragm |

The Importance of Pressure Regulation in Various Applications

Pressure regulation is crucial across many sectors, including manufacturing, hydraulics, and food processing. Maintaining the right pressure ensures safety and efficiency. According to industry reports, improper pressure levels can lead to equipment failure or product spoilage. A pressure regulator helps to manage these levels effectively.

In the manufacturing sector, precise pressure control can save costs. A 2022 report from the International Pressure Equipment Association noted that a 15% improvement in pressure management can reduce energy consumption. In hydraulics, accurate pressure regulation prevents system overloads, improving equipment lifespan.

In food processing, regulated pressure is vital for consistent product quality. Studies show that fluctuating pressure can alter a product's characteristics, risking consumer safety. A well-calibrated regulator helps maintain standards.

Tip: Invest in quality regulators and perform routine inspections to ensure effectiveness.

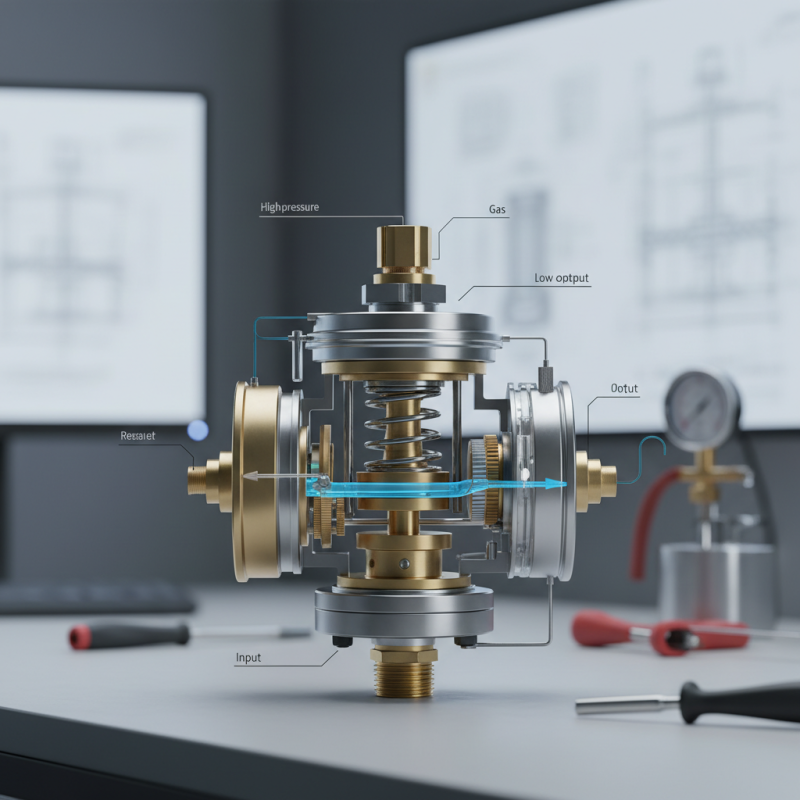

How a Pressure Regulator Functions: Key Components Explained

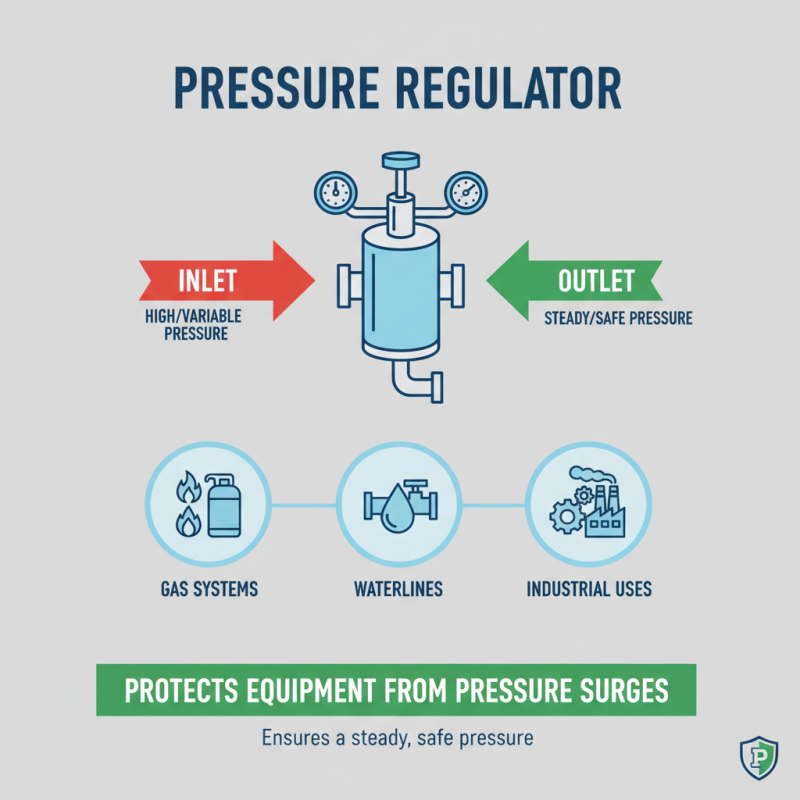

A pressure regulator is a device that controls the pressure of fluids within a system. It ensures a steady flow at a desired, safe pressure. These regulators are essential in gas systems, waterlines, and many industrial applications. They protect equipment from pressure surges.

Key components include the diaphragm, spring, and adjustment screw. The diaphragm senses the outlet pressure. It moves in response to changes. This movement adjusts the spring's position. As pressure varies, the regulator maintains a consistent output. According to a report from the International Society of Automation, efficient pressure regulation can reduce energy consumption by up to 30%.

Tips: Regularly inspect your pressure regulator for corrosion or damage. A faulty regulator can lead to leaks or inconsistencies in pressure. Ensure you use the right type for your application. An incompatible regulator might disrupt your system’s performance. Remember, even the best systems require periodic evaluation to ensure effectiveness. Small adjustments can yield significant efficiency gains.

Types of Pressure Regulators and Their Specific Uses

Pressure regulators are essential in various industries. They control the pressure of gases and liquids, ensuring safety and efficiency. Different types serve specific applications, each with unique functionalities.

One common type is the diaphragm pressure regulator. It uses a flexible diaphragm to modulate pressure. These are often used in residential gas systems. They keep gas pressure at safe levels, but sometimes they fail, leading to leaks. Regular maintenance is necessary to avoid potential hazards.

Another type is the spring-loaded pressure regulator. This device is widely used in industrial applications. Springs can be adjusted for different pressure settings, allowing flexibility. However, they may drift over time. Users need to recalibrate them periodically to maintain accuracy. Understanding the nuances of each type can enhance their effectiveness in practical applications.

Maintenance and Troubleshooting Tips for Pressure Regulators

Pressure regulators play a crucial role in maintaining consistent pressure levels in various systems. Regular maintenance is essential to ensure their optimal performance. According to industry reports, around 30% of pressure regulator failures stem from inadequate maintenance practices. This highlights the need for routine inspections and cleaning to avoid costly breakdowns.

Checking for leaks should be part of every maintenance routine. A small leak can lead to significant pressure loss and efficiency issues. Additionally, it can cause wear on the components. Inspecting diaphragm integrity is also vital. A damaged diaphragm can cause erratic pressure readings. Industry experts recommend replacing diaphragms every 3 to 5 years as a precaution.

Troubleshooting is necessary when issues arise. If the pressure fluctuates suddenly, consider possible obstructions or blockages. Sometimes, contaminants from the source can affect the regulator. Regularly replacing filters can minimize this risk. Ignoring these steps may lead to premature regulator failure. Keeping a detailed log of maintenance activities can help identify patterns in failures.

Related Posts

-

What is a Pressure Regulator and How Does It Work?

-

The Definitive Ultimate Guide to Pressure Regulators: Unlocking Consistent Performance and Efficiency

-

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Spray Nozzle for Your Needs

-

2026 Best Hose Reel Options for Easy and Efficient Gardening?

-

How to Choose the Right Power Washer Hose for Maximum Performance

-

Top 10 Pressure Washer Hose Reels for Efficient Cleaning in 2023